Arbeitsprinzip eines vertikalen Spänetrockners

Fachleute auf dem Gebiet der Ölförderung sind vertraut mit vertikale Spänetrockner, die dazu dienen, ölhaltigen Schlamm zu verarbeiten, ohne ihn auf den Boden fallen zu lassen. Was ist das Funktionsprinzip und der Arbeitsablauf eines vertikalen Spänetrockners? Das HL-Verkaufspersonal wird Ihnen heute eine kurze Einführung geben. Für ein tiefergehendes Verständnis von Bohrklein-Trocknern wenden Sie sich bitte an unsere Techniker.

Vertikale Bohrkleintrockner nutzen die Zentrifugaltrennung, um die festen und flüssigen Phasen des Bohrkleins zu trennen. Je nach der vom Kunden gewünschten Partikelgröße wählen wir Siebkörbe mit unterschiedlichen Schlitzen aus; der Schlitzbereich beträgt 0,25 bis 0,5 mm.

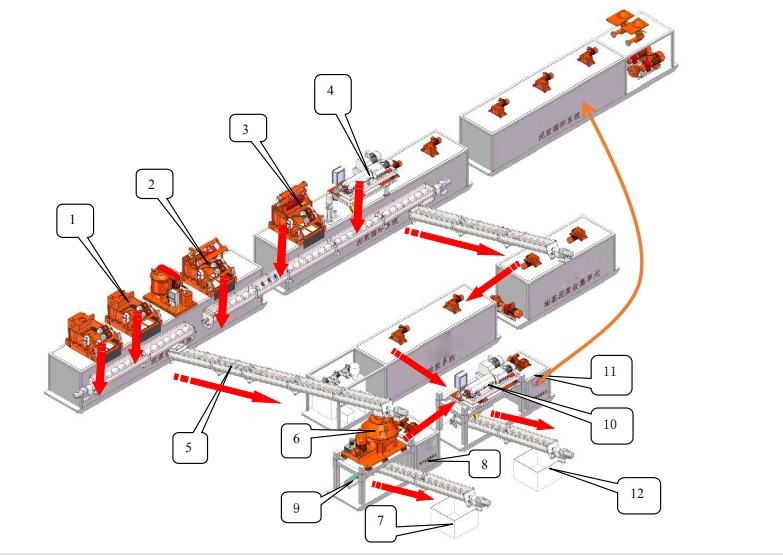

1. Schieferschüttler 2. Entsander 3. Entsander 4. Zentrifuge 5. Schneckenförderer 6. Vertikaler Spänetrockner 7. Vom Spänetrockner verarbeitetes Spänegut 8. Stecklingspackung 9. Schlammpumpe 10. Zentrifuge 11. Aufbereiteter Schlamm 12. Von der Zentrifuge aufbereitetes Bohrklein

Die aus dem Bohrlochkopf austretende Bohrspülung durchläuft den Schieferschüttler (1), den Entsander (2), den Desilter (3) und die Zentrifuge (4). Die Förderschnecke (5) transportiert sie dann zur weiteren Verarbeitung zum Trockner (6). Der Trockner (7) entlässt die Feststoffe direkt, und die zurückgewonnene Bohrspülung gelangt in den Schlammspeichertank (8). Die Schlammpumpe (9) fördert die Bohrspülung im Lagertank zur weiteren Trennung in die Zentrifuge (10). Die aufbereitete flüssige Phase (11) fließt zurück in den Bohrspülungszirkulationssystem, während die Zentrifuge die Feststoffe direkt ausschleust (12).

Xi'an HL Petroleum Equipment Co., Ltd. verfügt über ein Schlammvermeidungssystem (Schlammvermeidung auf Wasserbasis und Schlammvermeidung auf Ölbasis). Kunden mit diesem Bedarf können unseren Verkaufsleiter kontaktieren.