A sistema de refrigeración de lodoUn sistema de refrigeración del lodo, también conocido como sistema de control de la temperatura del lodo de perforación, mantiene la temperatura del fluido de perforación dentro de un rango deseado durante las operaciones de perforación. Este sistema de refrigeración evita que el lodo se sobrecaliente, lo que puede afectar negativamente al rendimiento de la perforación y a la integridad del equipo.

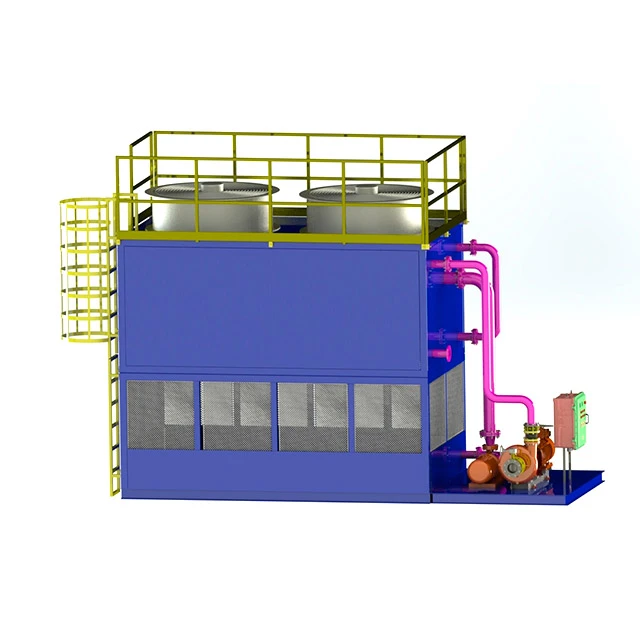

El sistema de refrigeración del lodo suele constar de varios componentes, como intercambiadores de calor, enfriadores, bombas y sistemas de control. El fluido de perforación circula a través de los intercambiadores de calor, donde intercambia calor con un medio refrigerante, como agua o aire. Esto ayuda a reducir la temperatura del lodo. El lodo enfriado se devuelve al sistema de lodo activo para su uso continuado.

El sistema de control supervisa y regula la temperatura del lodo, garantizando que se mantenga dentro del intervalo de funcionamiento especificado. Puede incluir sensores, válvulas y controles automatizados para mantener la estabilidad de la temperatura.

Parámetros técnicos

| Modelo | Capacidad de procesamiento | Tasa de enfriamiento | Presión de diseño | Huella | Notas |

| HNJLQ-150 | ≤150m³/h | ≤30℃ | 1,6Mpa | 15㎡ | temperatura de bulbo húmedo 28℃ |

Las ventajas de un enfriador de lodo son

1. Mejora del rendimiento de perforación: Al mantener la temperatura del lodo dentro del rango óptimo, el sistema de refrigeración ayuda a maximizar la eficiencia y la productividad de la perforación.

2. Aumento de la vida útil del equipo: El sobrecalentamiento del fluido de perforación puede provocar averías en los equipos y su desgaste prematuro. El sistema de refrigeración ayuda a prolongar la vida útil de los equipos de perforación al evitar una exposición excesiva al calor.

3. Mayor seguridad: El control de la temperatura del lodo contribuye a garantizar la seguridad del personal y los equipos de perforación. Un lodo sobrecalentado puede crear condiciones peligrosas y aumentar el riesgo de accidentes.

4. Cumplimiento de la normativa medioambiental: Algunas operaciones de perforación pueden tener normativas o directrices relativas a los límites de temperatura del lodo para proteger el medio ambiente. Un enfriador de lodo permite cumplir estos requisitos.

En general, un sistema de refrigeración de lodos desempeña un papel crucial en el mantenimiento de la temperatura del fluido de perforación, la optimización del rendimiento de la perforación y la protección del equipo y el personal en las operaciones de perforación.

HL Petroleum es un fabricante dedicado a la tecnología de refrigeración de lodos de perforación petrolífera. Nos especializamos en la fabricación de equipos para petróleo, gas natural, gas de esquisto, metano en capas de carbón, perforación geotérmica y otros campos, así como en el desarrollo y la aplicación de sistemas de purificación de circulación de fluidos de perforación. Tenemos una buena reputación en el mercado y experiencia en el diseño de soluciones específicas y fabricación de equipos. Para obtener más información sobre la tecnología de refrigeración de lodos de perforación de yacimientos petrolíferos, no dude en ponerse en contacto con nosotros.

Póngase en contacto con nosotros

Ventas: Control de sólidos HL

Correo electrónico: [email protected]