Panoramica del degassatore Poorboy

A degasatore poorboy è un dispositivo specializzato per il degassamento del fluido di perforazione immerso nel gas. La differenza principale tra un degasatore poorboy e un degasatore a vuoto è che può rimuovere le bolle di grandi dimensioni dal fluido di perforazione. In particolare, rimuove le bolle di diametro superiore a 3 mm per evitare blowout, calci e altri incidenti gravi.

Il separatore di gas di fango di Xi'an HL Petroleum può essere alimentato direttamente da un blowout preventer rotativo, oppure può essere utilizzato per separare le bolle di grandi dimensioni da un collettore di strozzatura. Il fluido di perforazione trattato, che contiene piccole bolle, viene quindi fatto vibrare da un agitatore di scisto. Dopo la vagliatura, entra nel degasatore a vuoto per il degasaggio convenzionale, completando il processo di degasaggio e garantendo le operazioni di perforazione.

Vantaggi del degasatore Poorboy

1. Struttura ottimizzata dell'apparecchiatura, ingombro ridotto e aspetto elegante;

2. Eccellente feedback degli utenti sul campo, poche parti soggette a usura ed elevata economicità.

3. I materiali selezionati garantiscono una qualità affidabile.

4. Hanno lucidato e sabbiato l'intera attrezzatura prima di verniciarla con un primer epossidico ricco di zinco, una vernice intermedia epossidica a base di ferro micaceo e una vernice di finitura poliuretanica. Abbiamo utilizzato la spruzzatura airless ad alta pressione per migliorare la resistenza alla corrosione e l'estetica dell'apparecchiatura.>>Invia una richiesta [email protected]<<

Parametri tecnici del degasatore Poorboy

| Modello | HYQ800 | HYQ1000 | HYQ1200 | HYQ1400 |

| Capacità di movimentazione dei liquidi | 6000m³/d | 7000m³/d | 8000m³/d | 8000m³/d |

| Capacità di gestione del gas | 100000m³/d | 120000m³/d | 147000m³/d | 147000m³/d |

| Diametro del cilindro | 800 mm | 1000 mm | 1200 mm | 1400 mm |

| Volume del cilindro | ≥1.6m³ | ≥3.0m³ | ≥4.0m³ | ≥6.0m³ |

| Pressione massima Pressione di lavoro | 1,0MPa | 1,0MPa | 1,0MPa | 1,0MPa |

| Diametro di uscita del gas | 159(6'')mm | 219(8'')mm | 219(8'')mm | 219(8'')mm |

| Diametro di uscita del liquido | 219(8'')mm | 219(8'')mm | 273(10'')mm | 273(10'')mm |

| Diametro di ingresso | 133(5'')mm | 133(5'')mm | 133(5'')mm | 133(5'')mm |

| Dimensione | 1900X1900X5700mm | 2150X1960X4900mm | 2400X2000X6130mm | 2700X2600X7400mm |

| Peso | 1900KG | 2300KG | 3500KG | 3800KG |

HL Petroleum supporta i servizi OEM. Se altre specifiche di degassificatore povero ragazzo che stai cercando, si prega di>>Invia una richiesta [email protected]<<

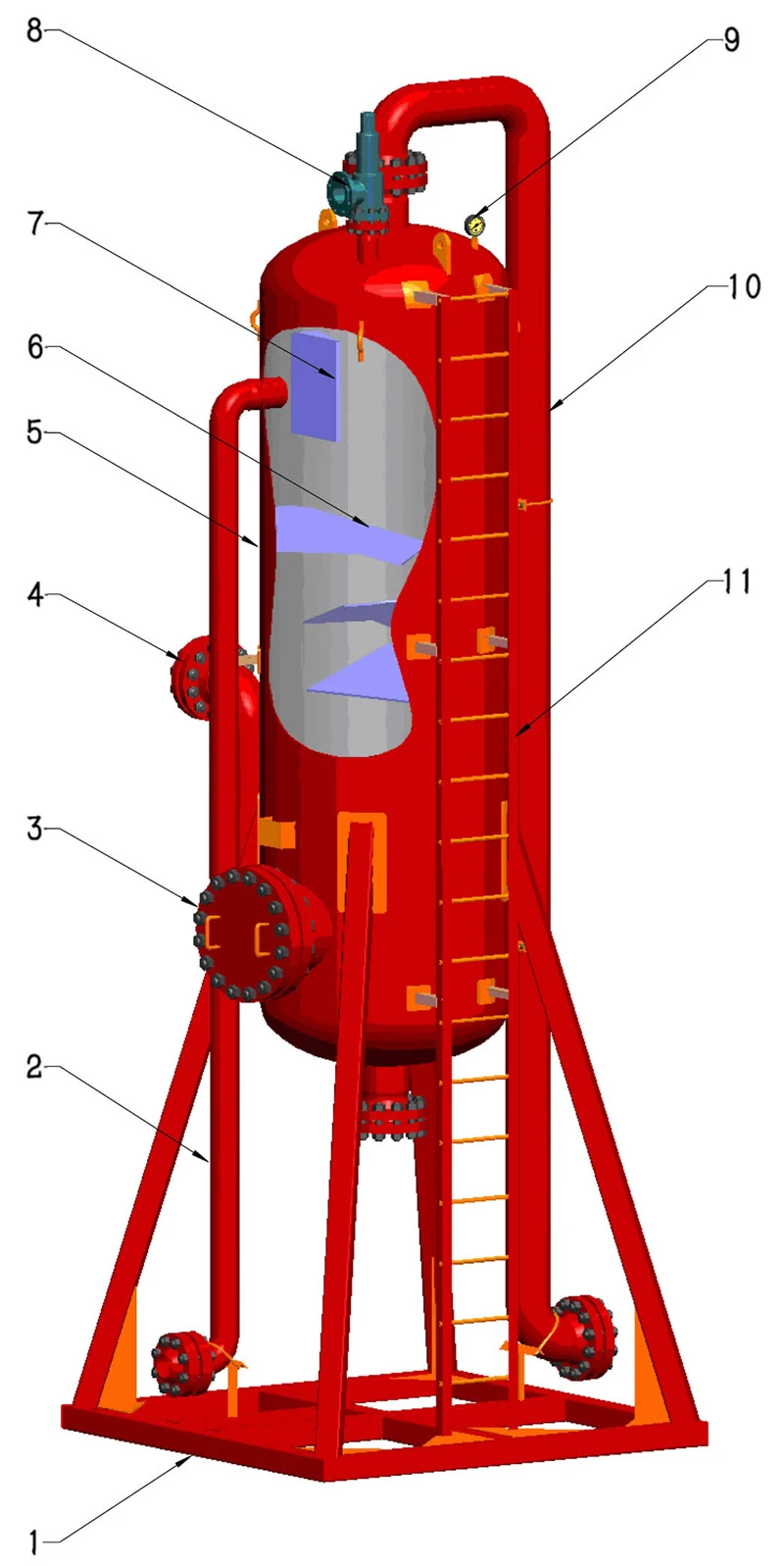

Struttura del degassatore Poorboy

1-Base 2-Tubo di alimentazione 3-Fosso di scarico 4-Tubo di scarico 5-Canale 6-Baffle

7-Piastra d'impatto 8-Valvola 9-Misuratore di pressione 10-Tubo di scarico 11-Lavetta

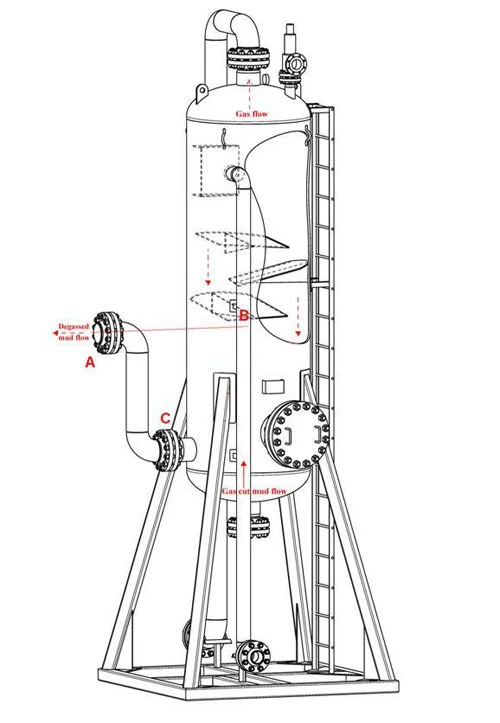

Principio di funzionamento del separatore di gas di fango

Il fluido di perforazione invaso dal gas entra nel separatore all'ingresso. Dopo aver urtato la piastra d'impatto, si disperde su una serie di diaframmi interni. Le bolle scoppiano e si separano dal fluido di perforazione.

Nella figura fornita, i punti A, B e C creano una struttura a forma di U che impedisce al gas di fuoriuscire attraverso la porta di scarico. Il gas viene invece scaricato attraverso l'uscita in cima al serbatoio e diretto in un luogo sicuro. La lunghezza del tubo di scarico viene determinata in loco. Al termine di questo processo, il fluido di perforazione degassato viene scaricato attraverso un vaglio vibrante in un serbatoio di circolazione, dove una degasatore sottovuoto degassifica ulteriormente.

Contatto

Vendite: HL Petroleum

E-mail: [email protected]