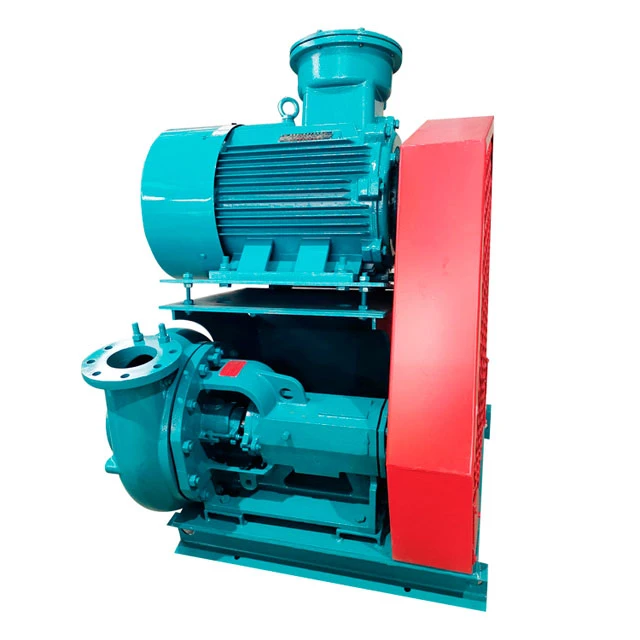

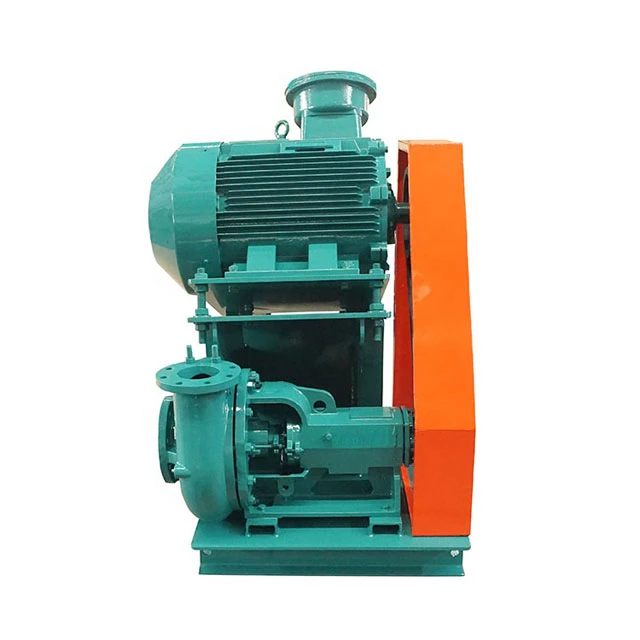

Shear pump is solids control equipment used for rapid mud preparation and processing in oil drilling and shield tunneling operations. They meet the requirements for high-performance mud preparation. They effectively mix and fully hydrate the materials added to the drilling fluid, saving on mud material usage, shortening mud preparation time, and ensuring excellent mud performance during the drilling process.

I. Function

1. Shear pumps significantly improve the hydration of soil particles.

2. The dispersion and hydration of soil particles in water depend on the electrolyte content, time, temperature, and the number and concentration of surface replaceable cations. Under the same conditions, using a drilling fluid shear pump can save over 30% of bentonite.

3. Drilling fluid shear pumps accelerate the shear dilution and hydration of polymers.

4. The high molecular weight of polymers used in mud makes them difficult to hydrate if added directly. Therefore, pre-shearing is required. Shear pumps provide high shear efficiency, accelerating the dilution and hydration of polymers. They offer high displacement and head, meeting the requirements of mud preparation and processing.

II. Structure and Operating Principle

1. The shear pump consists of an impeller, volute, support, packing box, drive shaft, pulley, combined belt, motor, and support.

2. The impeller of a drilling fluid shear pump differs from that of a typical water pump and has a more complex structure.

3. It is the core component of the shear pump and offers high shear efficiency. The impeller consists of five main parts: an axial-flow turbine, a fluid reservoir, an impeller, a plenum chamber, and a shear plate. The axial-flow turbine, impeller, and fluid reservoir are precision-cast as a single unit from stainless steel, resulting in a very compact structure.

4. The axial-flow turbine provides fluid with a certain displacement and capacity to the impeller and fluid reservoir. 50% of this fluid is discharged through the impeller into the volute, and 50% is absorbed by the fluid reservoir. The unique design of the plenum chamber imparts a certain amount of energy to the fluid in the reservoir.

5. The fluid discharged from the impeller flows parallel to the shear plate, achieving a high velocity. The fluid drawn into the fluid reservoir is ejected perpendicularly to the shear plate through 44 nozzles.

6. After the jet fluid mixes with the fluid discharged from the impeller, it impacts the outer teeth of the shear plate at a high velocity. The rapidly rotating shear plate teeth further shear the fluid. Therefore, the fluid flowing through the impeller is subjected to multiple shearing events.

III. Precautions

1. You cannot use this pump in active mud systems, as these systems contain large amounts of sand, which can easily damage the shear pump.

2. After use, flush it with clean water to prevent blockage of the impeller flow passage and nozzle.

3. During operation, the high shear velocity can easily cause fluid vaporization.

4. If the pressure gauge shows no pressure or fluctuates excessively, immediately shut down the pump and vent the pump.

5. During field drilling fluid operations, drain the pump completely in winter to prevent freezing and cracking.

Contact Us

Sales: HL

E-mail: [email protected]