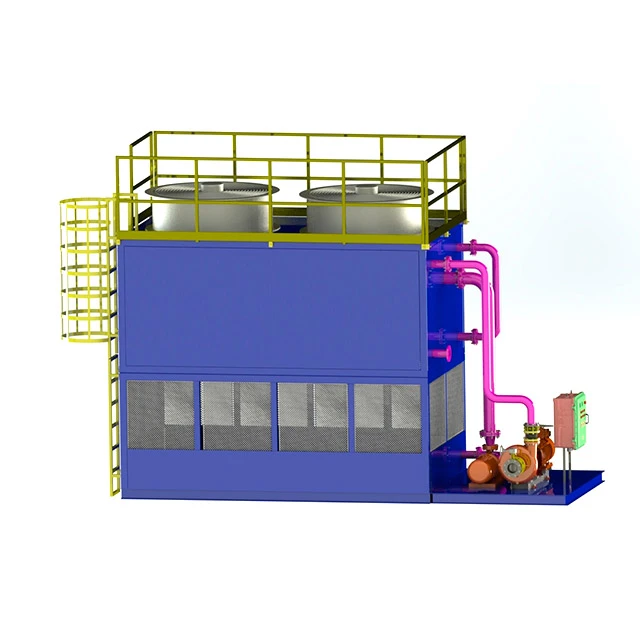

A system chłodzenia błotemSystem chłodzenia płuczki, znany również jako system kontroli temperatury płuczki wiertniczej, utrzymuje temperaturę płynu wiertniczego w pożądanym zakresie podczas operacji wiercenia. Ten system chłodzenia zapobiega przegrzaniu płuczki, co może negatywnie wpłynąć na wydajność wiercenia i integralność sprzętu.

System chłodzenia płuczki składa się zazwyczaj z różnych elementów, w tym wymienników ciepła, agregatów chłodniczych, pomp i systemów sterowania. Płyn wiertniczy przepływa przez wymienniki ciepła, gdzie wymienia ciepło z medium chłodzącym, takim jak woda lub powietrze. Pomaga to obniżyć temperaturę płuczki. Schłodzona płuczka jest następnie zawracana do aktywnego systemu płuczkowego w celu dalszego wykorzystania.

System sterowania monitoruje i reguluje temperaturę płuczki, zapewniając, że pozostaje ona w określonym zakresie roboczym. Może on obejmować czujniki, zawory i zautomatyzowane elementy sterujące w celu utrzymania stabilności temperatury.

Parametry techniczne

| Model | Zdolność przetwarzania | Szybkość chłodzenia | Ciśnienie projektowe | Ślad | Uwagi |

| HNJLQ-150 | ≤150m³/h | ≤30℃ | 1,6 MPa | 15㎡ | temperatura termometru mokrego 28℃ |

Zalety chłodnicy błota obejmują

1. Lepsza wydajność wiercenia: Utrzymując temperaturę płuczki w optymalnym zakresie, system chłodzenia pomaga zmaksymalizować wydajność i produktywność wiercenia.

2. Wydłużona żywotność sprzętu: Przegrzanie płynu wiertniczego może prowadzić do awarii sprzętu i jego przedwczesnego zużycia. System chłodzenia pomaga wydłużyć żywotność sprzętu wiertniczego, zapobiegając nadmiernemu narażeniu na ciepło.

3. Zwiększone bezpieczeństwo: Kontrolowanie temperatury płuczki pomaga zapewnić bezpieczeństwo personelu i sprzętu wiertniczego. Przegrzana płuczka może stwarzać niebezpieczne warunki i zwiększać ryzyko wypadków.

4. Zgodność z przepisami dotyczącymi ochrony środowiska: Niektóre operacje wiertnicze mogą mieć przepisy lub wytyczne dotyczące limitów temperatury płuczki w celu ochrony środowiska. Chłodnica płuczki umożliwia spełnienie tych wymagań.

Ogólnie rzecz biorąc, system chłodzenia płuczki odgrywa kluczową rolę w utrzymywaniu temperatury płynu wiertniczego, optymalizacji wydajności wiercenia oraz ochronie sprzętu i personelu podczas operacji wiertniczych.

HL Petroleum jest producentem zajmującym się technologią chłodzenia płuczki wiertniczej. Specjalizujemy się w produkcji sprzętu do wydobycia ropy naftowej, gazu ziemnego, gazu łupkowego, metanu z pokładów węgla, wierceń geotermalnych i innych dziedzin, a także w opracowywaniu i stosowaniu systemów oczyszczania cyrkulacji płuczki wiertniczej. Mamy dobrą reputację rynkową i doświadczenie w projektowaniu konkretnych rozwiązań i produkcji sprzętu. Aby uzyskać więcej informacji na temat technologii chłodzenia płuczki wiertniczej, prosimy o kontakt.

Kontakt

Sprzedaż: HL Solids Control

E-mail: [email protected]