Piese Agitator noroi

一. Piese de amestecare a miezului (contact direct cu noroiul)

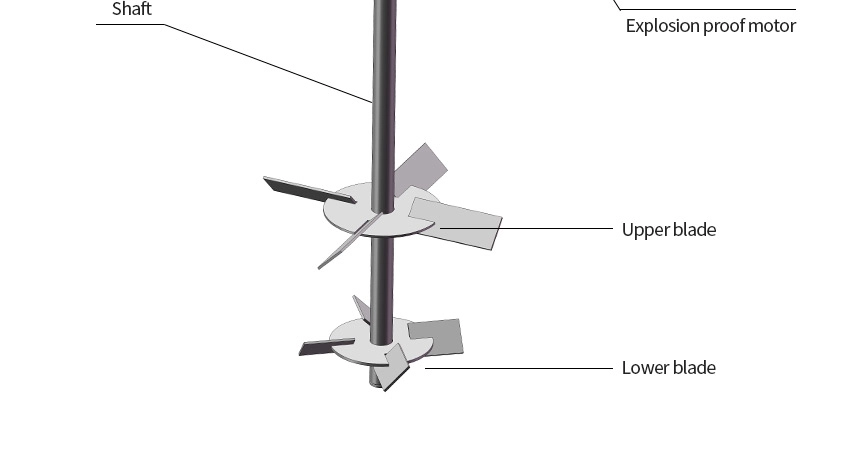

1. Rotor/paleta de agitare:

- Aceasta este cea mai critică parte, responsabilă pentru generarea mișcării fluidului, amestecarea și agitarea.

- Diferite tipuri: tip elice, tip turbină, tip paletă, tip ancoră etc., selectate în funcție de vâscozitatea noroiului, densitatea și scopul de agitare.

- Material: oțel carbon, oțel inoxidabil (304, 316L), oțel rezistent la uzură, acoperire din cauciuc poliuretanic, acoperire din cauciuc, materiale plastice tehnice (cum ar fi UHMW-PE) etc., trebuie să fie selectate în funcție de corozivitatea și abrazivitatea noroiului.

2. Arbore de agitare:

- Conectați dispozitivul de acționare (reductor/motor) și rotorul pentru a transmite cuplul.

- Material: De obicei, oțel carbon sau oțel inoxidabil. Este posibil ca arborii lungi să trebuiască să fie proiectați în secțiuni și susținuți de rulmenți intermediari.

- Accesorii: Bucșă (arbore de protecție), cheie (transmisie cuplu), flanșă/racord de conectare arbore.

3. Etanșare mecanică/etanșare arbore:

- Accesorii extrem de importante! Împiedică scurgerea noroiului din poziția în care arborele de agitare trece prin rezervor.

- Tip: Etanșare mecanică cu un singur capăt, etanșare mecanică cu două capete (cu sistem de izolare a fluidului, utilizat pentru medii de înaltă presiune și cu risc ridicat), garnitură de etanșare (stil mai vechi, întreținere frecventă).

- Accesorii: Cameră de etanșare, inel static, inel dinamic, arc, O-ring / garnitură, rezervor de lichid de izolare și conductă (pentru etanșare cu capăt dublu), gland.

二. Componente de acționare și transmisie

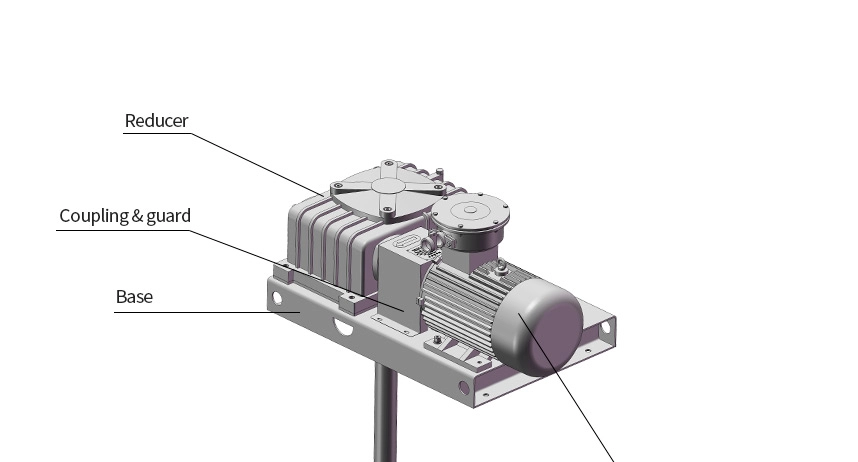

4. Motor reductor:

- Furnizează putere și reduce viteza și crește cuplul. Este sursa principală de energie a agitatorului.

- Tip: Reductor cu roți dințate (arbore paralel, arbore în unghi drept), reductor cu roți dințate cicloidale, reductor cu roți dințate fără sfârșit etc.

- Accesorii: Motorul în sine, cutia reductorului, garnitura de ulei, ulei/gras lubrifiant.

5. Reductor

- Convertește puterea de intrare de mare viteză și cuplu redus de la motor în puterea de ieșire de mică viteză și cuplu ridicat necesară arborelui agitatorului.

6. Cuplaj:

- Conectează arborele de ieșire al reductorului și arborele agitatorului, compensează erorile de instalare și transmite cuplul.

- Tip: Cuplaj cu știft elastic, cuplaj plum, cuplaj pentru anvelope, cuplaj cu diafragmă, etc.

7. Baza motorului/suport de montare:

- Sprijiniți și fixați motorul reductor pe partea superioară a rezervorului sau pe structura de susținere. Trebuie să se asigure rigiditatea și orizontalitatea.

三. Componente de asistență și instalare

8. Suport/cadru:

- Instalați ferm întregul agitator (motor, reductor, arbore, rotor) pe peretele superior sau lateral al rezervorului de amestecare.

- Inclusiv flanșa superioară, placa de montare cu intrare laterală, grinda de susținere etc.

9. Rulmentul și scaunul rulmentului:

- Rulment intermediar/rulment inferior: Pentru agitatoarele cu axă lungă, rulmenții sunt amplasați în mijlocul sau în partea inferioară a rezervorului pentru a reduce devierea arborelui și a asigura o funcționare stabilă.

- Accesorii: scaun de rulment, rulment de rulare (rulment cu bile cu caneluri adânci, rulment sferic cu role etc.) sau rulment glisant, dispozitiv de lubrifiere, capac de protecție.

10. Flanșă de montaj/placă de montaj:

- Asigurați o conexiune etanșă și rigidă între agitator și deschiderea rezervorului.

- Accesorii: corp flanșă, garnitură de etanșare (cauciuc, politetrafluoroetilenă etc.), șuruburi și piulițe.

四. Alte accesorii și piese de uzură

11. Capac de protecție:

- Protejați cuplajele rotative și alte piese pentru a preveni contactul uman și pătrunderea obiectelor străine.

12. Accesorii pentru sistemul de lubrifiere:

- Cupa de ulei, duza de ulei, conducta de ulei lubrifiant, indicatorul de nivel al uleiului (pentru lubrifierea reductorului și a rulmenților).

13. O-ring-uri, garnituri, inele de etanșare:

- Utilizat în diferite puncte de etanșare statică (cum ar fi conexiunile flanșei, capacele de capăt) pentru a preveni scurgerile. Materialul trebuie să fie compatibil cu noroiul.

13. Șuruburi, piulițe, șaibe:

- Se utilizează pentru fixarea între componente. Materialul este de obicei oțel carbon sau oțel inoxidabil, iar protecția împotriva coroziunii trebuie luată în considerare.

14. Căptușeală/înveliș rezistent la uzură:

- Instalate în apropierea peretelui rezervorului sau a rotorului pentru a proteja rezervorul sau echipamentul de eroziunea și uzura particulelor de noroi de mare viteză. Materialele sunt utilizate în mod obișnuit cauciuc rezistent la uzură, ceramică rezistentă la uzură, UHMW-PE etc.

15. Legat de sistemul de control (opțional):

- Invertor (pentru reglarea vitezei), demaror motor, releu termic, dulap de comandă, comutator/senzor de nivel al lichidului (control de blocare) etc.