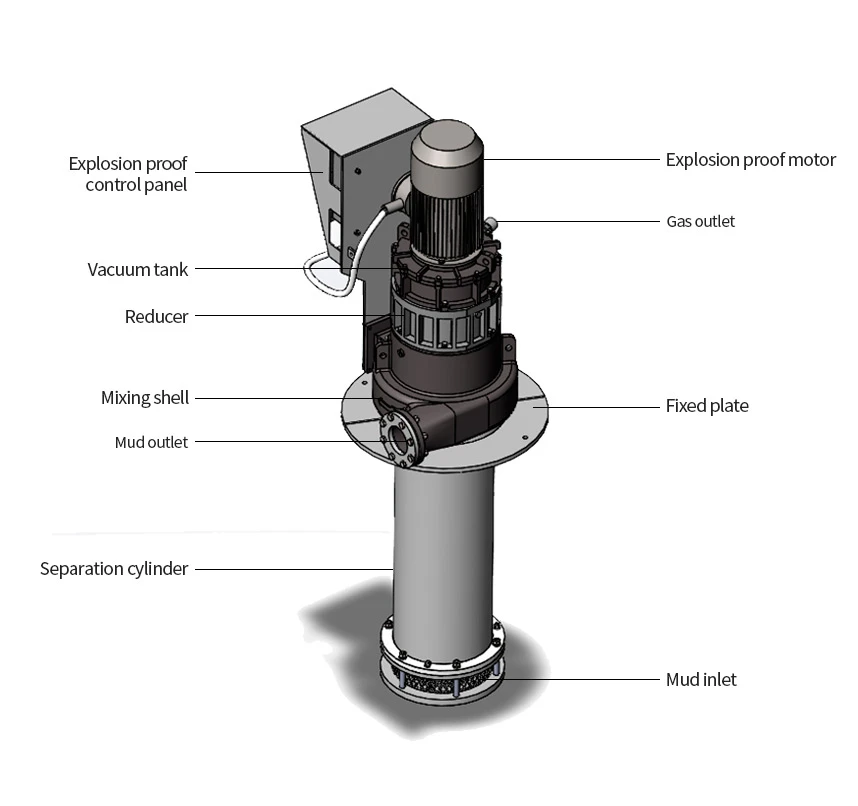

A центробежный дегазатор состоит из двигателя, выпускного насоса и понижающего редуктора. Это относительно новое устройство, в котором для разделения газов используется принцип центробежной сепарации. В настоящее время центробежные дегазаторы используются на буровых платформах.

Центробежный дегазатор - это новый тип дегазационного оборудования, которое представляет собой специальное оборудование для обработки бурового раствора с проникновением газа. Обычно устанавливается после вибросита. Оно подходит для совмещения с различными системами очистки бурового раствора. Он играет важную роль в восстановлении удельного веса бурового раствора, стабилизации вязкостных характеристик бурового раствора и снижении затрат на бурение.

Преимущества центробежных дегазаторов

1. Использует вакуумный насос для всасывания, что обеспечивает высокую эффективность выхлопа.

2. Уникальная конструкция редуктора обеспечивает плавную работу и постоянную скорость.

3. Длинные лопасти для разделения жидкости и газа увеличивают ход разделения и повышают эффективность разделения газа и жидкости.

4. Новое устройство для удаления шлама значительно увеличивает пропускную способность бурового раствора.

5. Рациональная, компактная конструкция обеспечивает превосходные эксплуатационные характеристики.

Технические параметры центробежного дегазатора

| Модель | HLCQ240 | HLCQ300 |

| Вместимость | 240 м3/ч | 300 м3/ч |

| Мощность двигателя | 11 кВт | 18,5 кВт |

| Эффективность сепарации | >= 85% | >=85% |

| Напряжение | 380V/50HZ 3 фазы | |

| Размер | 2750*1185*1105 мм | 3570*1280*1000 мм |

| Вес | 900 кг | 1100 кг |

Применение и результаты

1. Улучшение характеристик бурового раствора: Удаляя из бурового раствора вредные газы, такие как сероводород, угарный газ и метан, система эффективно восстанавливает удельный вес и вязкость раствора, делая его более стабильным и повышая эффективность и качество бурения.

2. Защита оборудования: Значительно уменьшает коррозию и повреждение песчаных насосов, грязевых насосов и другого сопутствующего оборудования, вызванное вредными газами, продлевая срок службы оборудования.

3. Служит в качестве мешалки: Когда в буровой раствор не проникает газ, он может работать как мощная мешалка, помогая поддерживать однородность раствора.

4. Оптимизация системы контроля твердых частиц: Работая в сочетании с другим оборудованием для контроля твердых частиц (например, виброситами и центрифугами), система еще больше повышает общую эффективность очистки системы контроля твердых частиц, обеспечивая очистку и эффективную переработку буровых растворов.

Компания Xi'an HL Petroleum Equipment Co., Ltd. специализируется на производстве и разработке оборудования для контроля твердых частиц. Она предоставляет различные виды продукции и поддерживает индивидуальные услуги. Если вы заинтересованы в дегазаторе бурового раствора или других продуктах, добро пожаловать на консультацию. Вы можете связаться с нашим отделом продаж, чтобы узнать больше о технических характеристиках нашей продукции, вариантах настройки, ценах и многом другом. Мы искренне предоставим вам высококачественные продукты и профессиональные услуги.

Свяжитесь с нами

Продажи: HL Petroleum

E-mail: [email protected]