Hvad er komponenterne i en borevæske shale shaker?

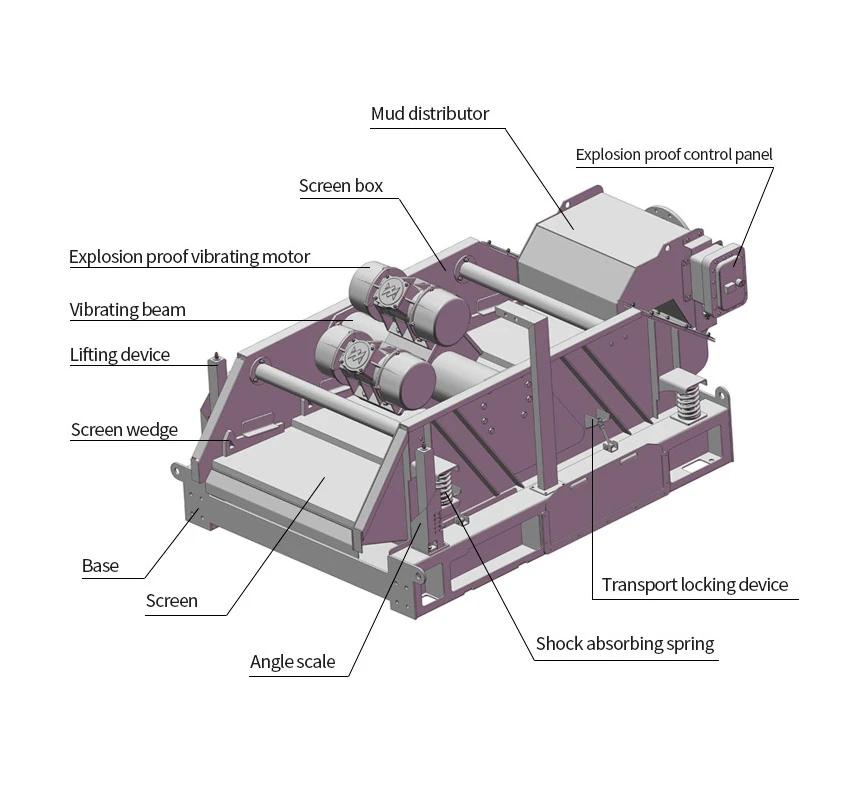

Reservoiret (ofte kaldet et forseglet styretrug eller en borevæsketank) på bagsiden af shale shakeren modtager borevæske fra overløbsrøret. Borevæsken strømmer gennem overløbsporten og spredes på ristedugens overflade. Vibrationer hjælper med at fjerne faste stoffer. Vibrationsisoleringsenheder, som findes i tre typer (spiralfjedre, luftpuder eller stenflåd), understøtter den vibrerende ramme. Isolationsenhederne hviler på skinner. En opsamlingsbakke under den vibrerende ramme opsamler den borevæske, der strømmer gennem screendugen, og sender den tilbage til cirkulationssystemet.

Vibrationsmønsteret, ristens slaglængde og motorhastigheden påvirker shale shakerens ydeevne. Vibrationsrammens installationsposition og vibrationsretning under risteoverfladen bestemmer risteoverfladens aksiale vibrationsretning og amplitude. Producenterne fremstiller mange forskellige vibrationsrammer og shale shaker-dugprodukter, og operatørerne kan installere dugen i en vinkel eller vandret. I skråtstillede installationer kan skærmdugen vippe opad eller nedad på den vibrerende ramme. Den vibrerende ramme kan installeres vandret eller vippes i en fast eller justerbar vinkel. Den justerbare hældningsvinkel gør det muligt for skærmoverfladen at svinge op og ned i overensstemmelse hermed.

I systemer med skråtstillede skærme (enten i serie eller parallelt) er skærm overflade kan være en enkelt, kontinuerlig skærmdug, sammensat af to eller flere separate skærmduge eller sammensat af flere skærmduge med varierende hældning. I systemer med sammensatte filterduge strømmer borevæsken gennem den første filteroverflade, før den strømmer til den nederste filteroverflade.

Ovenstående er nogle oplysninger om strukturen af borevæske shale shaker. Hvis du gerne vil vide mere om shale shaker eller overvejer at købe en, er du velkommen til at kontakte os. [email protected]