The lej Venturiego sprytnie wykorzystuje zasadę Venturiego. Gdy płyn przepływa przez wąską rurkę Venturiego z dużą prędkością, jego ciśnienie spada, generując potężną siłę ssącą. Podczas pracy szybko zasysa różne materiały i skutecznie miesza je z cieczą, działając jak doskonały mistrz mieszania. Powoduje to równomierne rozproszenie materiałów w cieczy, znacznie poprawiając wydajność i jakość mieszania, tworząc solidne podstawy dla kolejnych operacji.

Zbiorniki Venturiego mają szereg zalet, które czynią je popularnymi urządzeniami do mieszania płuczki wiertniczej:

1. prosta struktura

2. wysoka wykonalność

3. Bezpieczne i niezawodne działanie

4. Łatwość przenoszenia

5. Szybkie mieszanie

6. Wymieszać równomiernie

7. Niskie zużycie energii

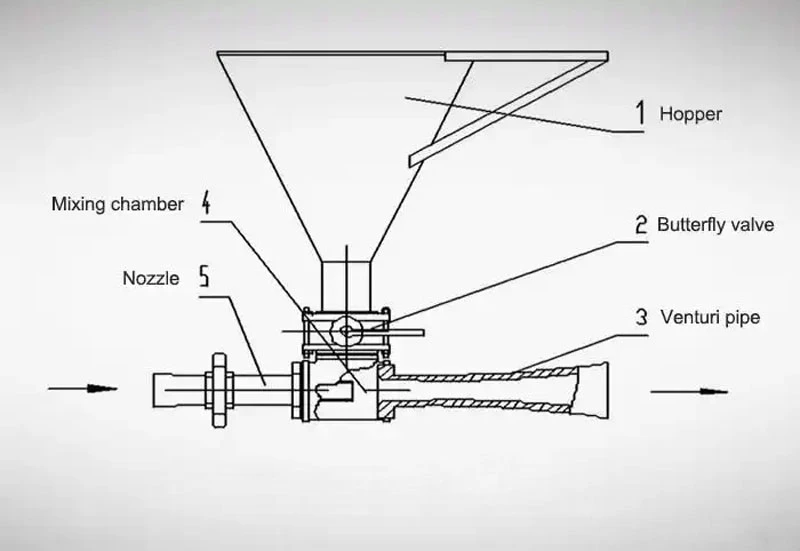

Zasada działania leja Venturiego

Po wyrzuceniu z dyszy ciecz przechodzi przez komorę mieszania i wchodzi do rury ścinającej. Materiał jest wprowadzany do komory mieszania przez lejek i, napędzany przepływem płynu z dyszy, wchodzi do rury ścinającej, gdzie jest rozpraszany i mieszany. Wymieszana ciecz wypływa z rury ścinającej do zbiornika recyrkulacyjnego.

Rura ścinająca to wydrążona rura, która stopniowo rozszerza się wzdłuż zakrzywionej powierzchni. Jej podstawową funkcją jest zwiększenie siły ścinającej wewnątrz rury, umożliwiając lepsze rozproszenie materiałów i podniesienie ciśnienia mieszanej cieczy przed jej wejściem do zbiornika recyrkulacyjnego.

Rura ścinająca skutecznie wykorzystuje efekt Bernoulliego: "szybszy przepływ, niższe ciśnienie; wolniejszy przepływ, wyższe ciśnienie". W komorze mieszania ciecz jest wyrzucana z dyszy z dużą prędkością, a ciśnienie jest w tym czasie niskie; po wejściu cieczy do rury ścinającej przekrój stopniowo się zwiększa, prędkość maleje, a ciśnienie wzrasta.