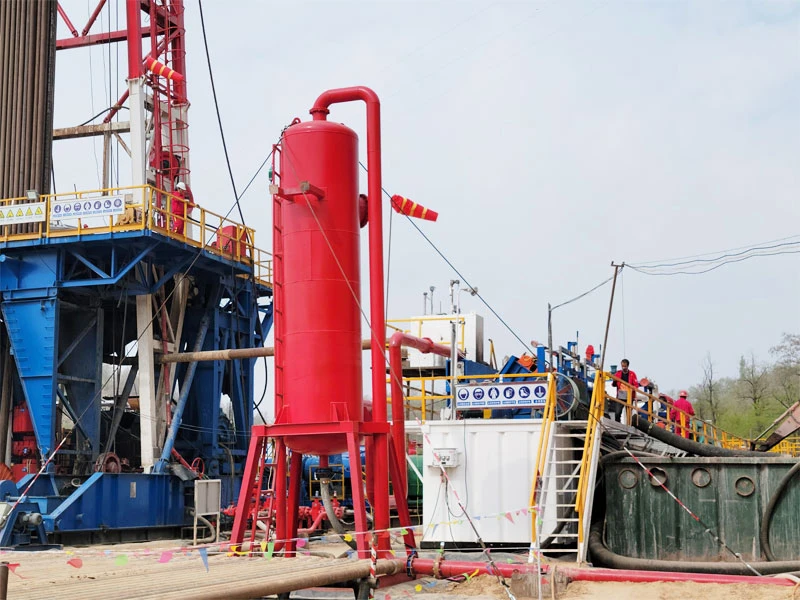

كيفية تركيب منظف الطين

استخدام الطريقة الصحيحة لتثبيت منظف الطين يمكن أن تمكن منظف الطين بشكل أفضل من تنظيف المراحل الصلبة الضارة في سائل الحفر، وتحسين أداء سائل الحفر، وتلبية متطلبات عملية الحفر النفاثة الجديدة عالية الضغط. اليوم، سيقدم لك محرر HL مقدمة موجزة.

(1) قم بتثبيت الإعصار الحلزوني متعدد الوظائف بعد هزاز الصخر الزيتي ووضعه على رقم 1 أو رقم 2 خزان سائل الحفر.

(2) يجب أن يعالج شاكر الصخر الزيتي سائل الحفر قبل دخوله إلى المنظف.

(3) قم بتشغيل الطاقة. بعد بدء تشغيل المحرك، تأكد من الانتباه إلى اتجاه دوران المحرك. يجب أن يتطابق اتجاه المحرك مع الاتجاه المحدد على الجزء الخارجي من واقي السير.

(4) أولاً، قم أولاً بتشغيل هزاز الصخر الزيتي بشكل خامل للتحقق مما إذا كان طبيعيًا. إذا وجد أي صوت غير طبيعي، أوقف الماكينة للفحص في الوقت المناسب.

(5) أحكم ربط الشاشة. أولاً، أحكم ربط الشاشة، واضغط على براغي الشد، واختبر الشاشة باليد. تحسس إحكام كل جزء. ثم قم بتشغيل الاختبار لمدة 2 ~ 3 دقائق. في هذا الوقت، يجب ألا تنفصل الشاشة والشريط المطاطي. ثم أحكم ربط البراغي بشكل مناسب وتحقق من نوابض الشد. يجب أن تكون أطوالها متماثلة بشكل أساسي.

كيفية الحفاظ على منظف الطين

(6) لا تستخدم أشياء صلبة، مثل المجرفة، لتنظيف الرمال المتراكمة. سيؤدي ذلك إلى تلف الشاشة.

(7) اشطف سطح الغربال بالماء مرة واحدة على الأقل في كل وردية، وإلا فإن المادة اللزجة والرمال الناعمة المحتجزة على سطح الغربال قد تسد الشبكة وتؤثر على الاستخدام العادي للغربال.

(8) عند إيقاف المنظف، قم أولاً بإيقاف مضخة الرمال، ثم اترك هزاز الصخر الزيتي يعمل في وضع الخمول لمدة 3 إلى 5 دقائق. وأخيرًا، اشطف سطح الغربال بالماء على الفور للحفاظ على نظافته قبل إيقاف هزاز الصخر الزيتي.

(9) قم بتشحيم محامل المثير مرة واحدة يوميًا لمنع حدوث تلف مبكر للمحامل بسبب نقص الزيت.

(10) أثناء الرفع والنقل، لا تضع أجسامًا صلبة على سطح الشاشة أو تدوس عليها بقدميك.

(11) منع الحطام من دخول الإعصار الحلزوني لمنع انسداد قناة تدفق عمل الإعصار الحلزوني وإتلاف الإعصار الحلزوني.

(12) يجب عليك شطف حوض تفريغ هزاز الصخر الزيتي والصفيحة السفلية بشكل متكرر بالماء لمنع تراكم الترسبات الكلسية في قاع الحوض.

اختيار حجم الشبكة للشاشة

يجب عليك تحديد الشاشة حجم الشبكة التي لا تجتاز الاختبار بناءً على ظروف التكوين وأداء سائل الحفر. إذا كان سائل الحفر يحتوي على لزوجة عالية ومحتوى رملي مرتفع، اختر مصفاة ذات حجم شبكي أصغر. خلاف ذلك، اختر مصفاة ذات حجم شبكة أعلى. يمكن للشاشة ذات نسبة طول التدفق لسائل الحفر على سطح الشاشة التي تبلغ حوالي p أن تعطي دورًا كاملاً لوظيفة شاكر الصخر الزيتي، وهو أمر مفيد للشاشة لإزالة البُرادة وزيادة عمر خدمة الشاشة.

عند استخدام المنظف، ابدأ تشغيل هزاز الصخر الزيتي الشبكي الدقيق أسفل الإعصار أولاً، ثم ابدأ تشغيل مضخة الرمل؛ وعند إيقاف تشغيل المنظف، أغلق مضخة الرمل أولاً، ثم أغلق هزاز الصخر الزيتي الشبكي الدقيق.

تذكير خاص: أثناء التركيب، يجب عليك التأكد من أن خزان شفط السائل وخزان التفريغ الفائض من ديساندر, ومزيل الترشيح ومنظف سائل الحفر متناسقة مع تسلسل دوران سائل الحفر. وإلا، سيقل تأثير تنقية جهاز إزالة الغبار ومزيل الترشيح.