Le forage prolongé d'un champ pétrolifère peut entraîner des températures de puits excessivement élevées. Les températures élevées réduisent la capacité d'hydratation de la surface des particules d'argile et de l'agent de traitement, ce qui amincit le film d'hydratation. Cela réduit considérablement l'effet protecteur des molécules de l'agent de traitement sur l'argile, ce qui augmente la perte d'eau dans la boue et provoque une solidification à haute température. Comment refroidir les fluides de forage à haute température ? Actuellement, il existe trois méthodes pour refroidir la boue de forage à haute température dans les puits géothermiques à haute température et les forages profonds : le refroidissement de la boue par conduction solide à basse température, le refroidissement de la boue par évaporation naturelle et le refroidissement forcé à l'aide d'un système de circulation pour le refroidissement de la boue.

1. Refroidissement de la boue par conduction solide à basse température

Les opérateurs ajoutent des solides froids, tels que des glaçons, à la mare de boue. Les glaçons refroidissent la boue principalement par conduction thermique. Cette méthode est généralement utilisée pour refroidir la boue à base d'eau lorsque la température de la boue en surface est basse et que la différence de température entre l'entrée et la sortie est faible.

2. Refroidissement naturel par évaporation de la boue

La température de la boue remontant à la surface étant plus élevée que la température ambiante, la boue s'évapore et se refroidit naturellement lorsqu'elle s'écoule dans l'auge à boue. En manipulant ce phénomène et en prolongeant la ligne de circulation de l'auge à boue, les opérateurs peuvent refroidir la boue dans une certaine mesure. Ils utilisent généralement cette méthode lorsque le débit de boue de forage est faible, que la température de retour de la boue n'est pas trop élevée (inférieure à 55°C) et que la différence de température entre les puits d'entrée et de sortie est faible (moins de 5°C).

3. Refroidissement forcé avec un système de refroidissement de la boue pour le forage

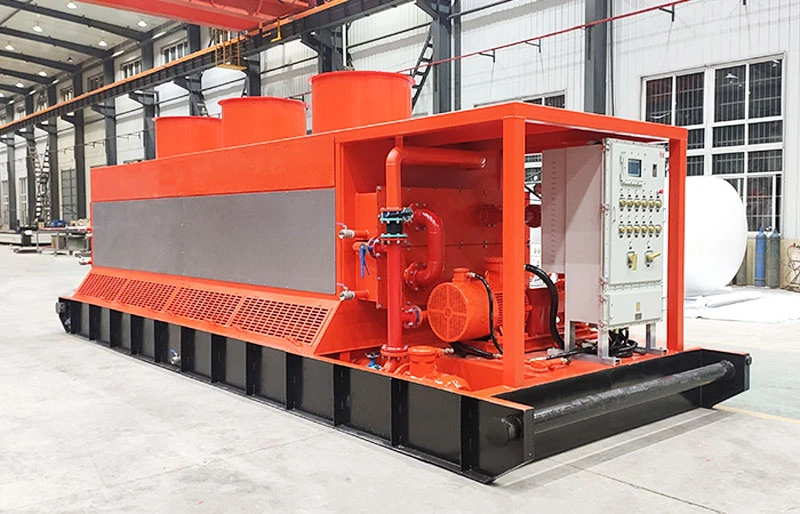

Un système de refroidissement de la boue de forage, également appelé unité de refroidissement de la boue ou tour de refroidissement de la boue, refroidit les fluides de forage. Dans les forages géothermiques à moyenne et haute température et dans les forages pétroliers et gaziers profonds, lorsque la température de la boue circulante dépasse 75°C, les équipes doivent utiliser une unité de refroidissement de la boue de forage pour un refroidissement rapide et opportun. Les équipes ont besoin d'une unité spécialisée de refroidissement de la boue ou d'un système de refroidissement de la boue lorsque la température de la boue de retour est élevée et que la différence de température entre les puits d'entrée et de sortie est trop importante. Un système de refroidissement de la boue permet un refroidissement forcé de la boue à haute température et constitue actuellement une méthode de refroidissement de la boue relativement efficace et sûre.

Les nouvelles installations de HL Petroleum, conçues et développées de manière indépendante, ont été mises en place dans le cadre d'un projet de développement de l'entreprise. système de refroidissement de la boue permet au fluide de forage chaud (boue) s'écoulant de la tête de puits d'être transporté vers le collecteur d'entrée du système par l'intermédiaire d'un collecteur. La différence de température entre le système de refroidissement de la boue et la boue traitée est de 30 à 40°C. Cela permet de prolonger la durée de vie du trépan et de la tige de forage tout en améliorant l'efficacité du forage. En outre, pour répondre aux variations de température de la boue dans les différents pays et régions, Henglian Petroleum a développé une gamme de dispositifs de refroidissement de la boue, y compris des dispositifs de refroidissement de la boue rapides et standard, pour répondre aux augmentations de température variables de la boue dans les différentes formations. Pour plus d'informations sur notre système de circulation pour le refroidissement des boues, veuillez nous contacter.