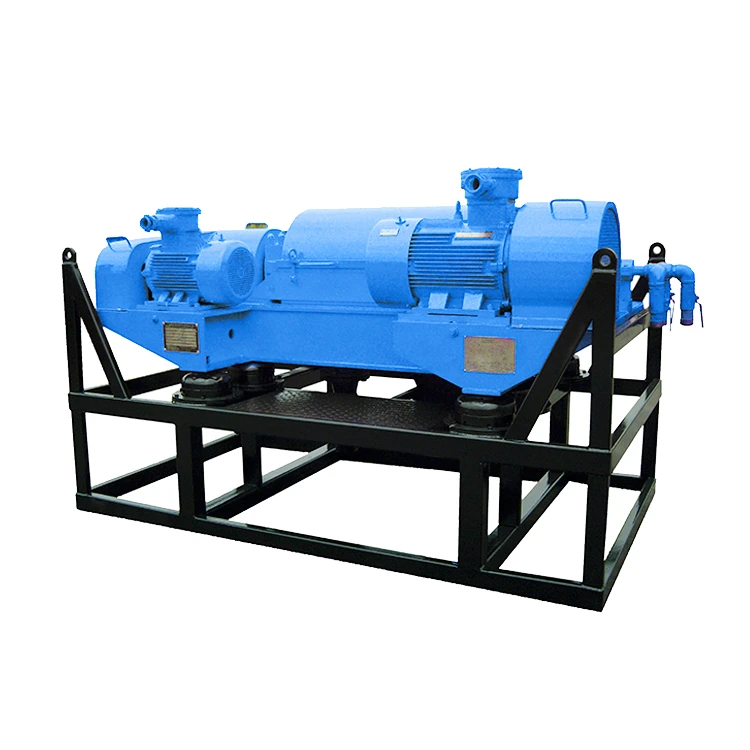

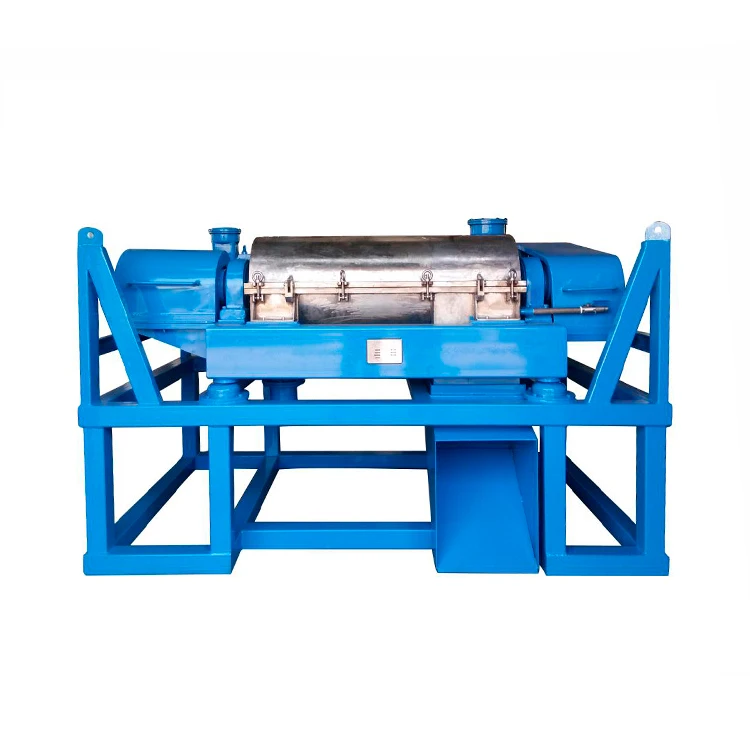

Drilling fluid centrifuge is usually horizontal spiral sedimentation centrifuges. Mud centrifuges are mainly used to process solid particles of 2 to 7 μm in drilling fluid. Centrifuges are the last stage of processing equipment in the solid control system.

The drilling fluid centrifuge is one of the important equipment for solid-liquid separation in solids control equipment. We usually install it at the last stage of the solids control system to remove harmful fine solid particles, such as cuttings, in the mud, which ensures fast and safe drilling. Alternatively, it recovers valuable heavy materials like barite and saves mud costs. We divide centrifuges into low-speed centrifuges, medium-speed centrifuges, and high-speed centrifuges, according to their working speed.

Technical Parameters of Drilling Fluid Centrifuge

| Model | LW355×1257-N | LW450×842-N | LW450×1000-N | LW500×1000-N | LW600×1000-N |

| Bowl Diameter(mm) | 355 | 450 | 450 | 500 | 600 |

| Bowl Length(mm) | 1257 | 842 | 1000 | 1000 | 1000 |

| Max. Capacity(m³/h) | 30 | 40 | 50 | 50 | 60 |

| Max Bowl Speed(rpm) | 3200 | 1800 | 2200 | 2500 | 1600 |

| Separation Factor | ≤2296 | ≤820 | ≤1218 | ≤1817 | ≤900 |

| Main Motor Power(KW) | 30 | 22 | 30 | 37 | 45 |

| Auxiliary Motor Power(KW) | 7.5 | 5.5 | 7.5 | 7.5 | 7.5 |

| Dimension:Lx Wx H(mm) | 3000×1500×1650 | 2370×1700×1800 | 2580×1700×1850 | 2660×1670×1760 | 3060×1870×1790 |

| Weight(kg) | 3300 | 2950 | 3300 | 3400 | 3500 |

Remarks: The above models all have medium-high speed and frequency conversion models, please let us know when you place an order.

Drilling Fluid Centrifuge Features

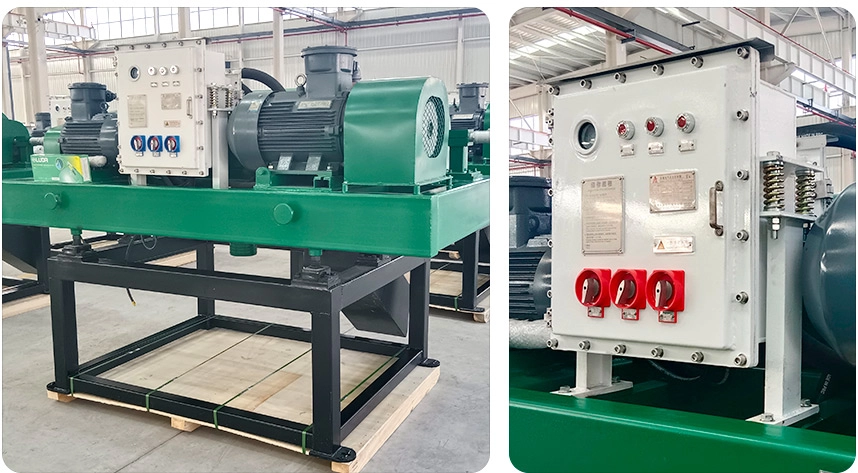

This series of oilfield decanting centrifuges uses a hydraulic coupling to drive the drum. They adjust the spiral speed through a planetary gear differential to achieve low-speed and high-torque power transmission, and we equip them with mechanical and electrical double overload protection devices. The inner spirals all feature cemented carbide inserts, and we design them with a special suspension structure. The blades are highly resistant to wear and the whole machine has a large processing capacity.

Drilling Fluid Centrifuge Application

There are two main reasons for using centrifuges in the drilling fluid maintenance process:

(1) Selective separation and aggravation of colloidal particles and ultrafine particles in the drilling fluid.

(2) Remove fine particles in non-aggravated drilling fluid

HL Petroleum provides OEM services for clients worldwide,designs centrifuge mud cleaning system,sludge dewatering centrifuge, centrifuge drilling mud system, not only for oil and gas drilling rigs, but also trenchless hdd projects,Geothermal drilling,etc.