What are the different types of agitators? Let’s first understand the classification method of mud agitators. Mud agitators can be classified according to different reducer motor connection methods, different impeller structures, different stirring media, different uses, and other factors. Different classifications have different agitator types. According to the reducer connection method, we can divide it into turbine worm type and helical gear type. Based on the impeller’s structure, we can categorize it into flat blade, folded blade, and spiral blade mud agitators. Depending on the fluid flow, we can classify it into axial flow, radial flow, and mixed flow mud agitators. Finally, according to its use, we can separate it into low-viscosity fluid and high-viscosity fluid mud agitators.

The following divides mud agitators into three types according to the different fluid flow directions: turbine type, propulsion type, and paddle type.

1. Turbine mud agitator

The turbine mud agitator is the most commonly used agitator type in the drilling fluid mixing process. It can effectively complete almost all mixing operations and can handle fluids with a wide range of viscosities. It is an agitator for low-viscosity fluids. Turbine agitators can be divided into open type and disc type. The open type has straight blades, inclined blades, curved blades, etc., and the disc type has disc straight blades, disc inclined blades, disc curved blades, etc. The number of blades commonly used in open turbines is 2 blades and 4 blades, and the disc type is most common with 6 blades. The turbine agitator has a large shear force, which can disperse the fluid micro-groups very finely. It is suitable for mixing, liquid-liquid dispersion, and liquid-solid suspension of low-viscosity to medium-viscosity fluids. The straight blade has a large shear effect and is a shear type agitator. Curved blades refer to blades that bend in the direction of flow, which can reduce power consumption and are suitable for mixing fluids containing fragile solid particles.

2. Propeller mud agitator

The standard propeller agitator has three-lobed blades, and its pitch is equal to the paddle diameter d. The turbulence of the fluid is not high when the propeller agitator is stirring, but the circulation volume is large. The propeller agitator has a simple structure and is easy to manufacture. It is often used in low-viscosity fluids and is suitable for occasions with low viscosity and large flow. It has good circulation performance and little shear effect, and is a circulation type agitator. The diameter of the propeller agitator is smaller, d/D=1/4-1/3, the blade tip speed is generally 7-10m/s, and the maximum can reach 15m/s.

3. Paddle mud agitator

We make the blades from flat steel and fix them to the hub by welding or bolts. The number of blades is 2, 3, or 4, and we can divide the blades into two types: straight blade type and folding blade type. Paddle agitators mainly circulate fluid. Since the folding blade type consumes less power than the flat blade type under the same displacement, we use axial flow blades more frequently. The so-called axial flow blade means that the main discharge direction of the blade is parallel to the stirring shaft. Paddle agitators can also be used for stirring high-viscosity fluids to promote the upper and lower exchange of fluids, replacing the expensive spiral ribbon impeller. The speed of the paddle agitator is generally 20-100r/min, and the maximum viscosity is 20Pa.s.

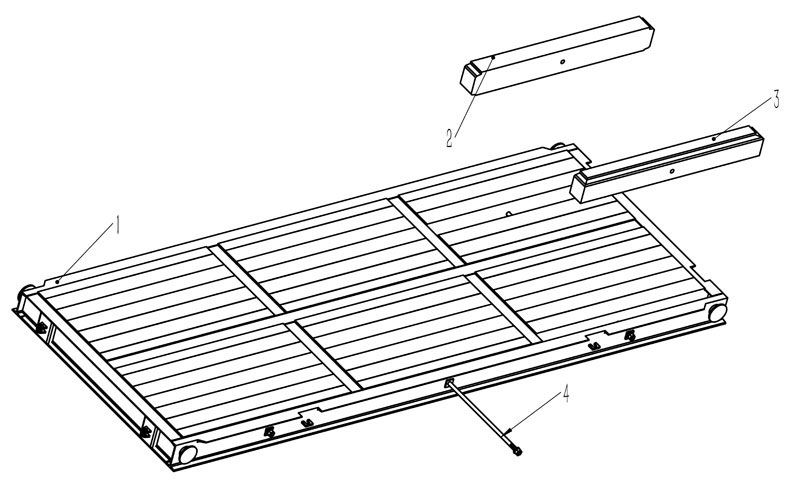

Mud agitator structure composition

The above are the differences between the three types of mud agitators: turbine type, propeller type, and paddle type. In addition to these three types, there are many other types of mud agitators. Currently, the mud agitators used in oilfield drilling solids control are mainly turbine worm type.