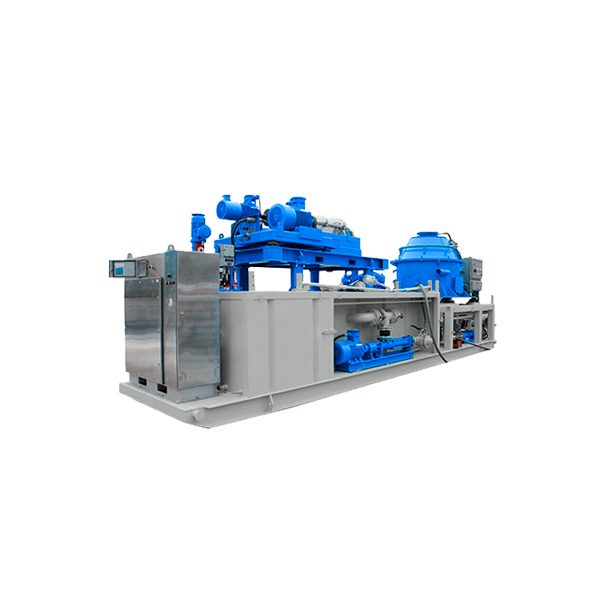

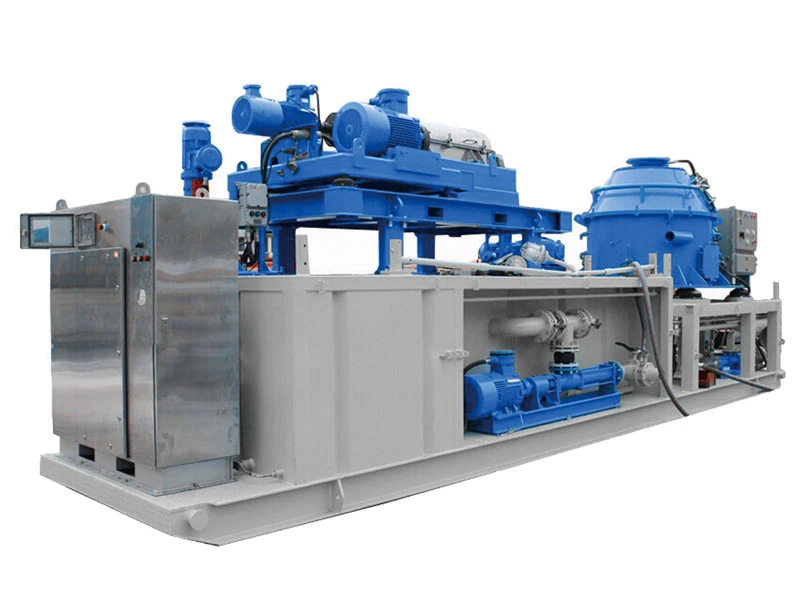

The drilling cuttings waste management consists of a high-speed drilling fluid centrifuge (with a screw pump), a cuttings dryer (also called a cuttings dryer, a cuttings drying machine, and a cuttings drying machine) ), dosing device, screw conveyor, cuttings box, etc.

We feed the drill cuttings discharged from the conventional solid control system to the drill cuttings dryer for drying via a screw conveyor. After drying, we transport the solid phase to the collection tank. The separated liquid phase enters the storage box, and a liquid supply pump feeds it to the high-speed variable frequency centrifuge for mud and water separation. We transport the treated solid residue to the collection tank, and we recycle the treated drilling fluid. We uniformly collect the drill cuttings and solid residue treated by the dryer and centrifuge, and then we stir and solidify them by adding chemicals.

Drilling Cuttings Waste Management System Treatment Process

We transport the drilling fluid for processing to the cuttings dryer (also known as a cuttings drying machine or drilling cuttings drying machine). We then send the treated drilling fluid mud to the drilling fluid centrifuge for further processing. After the drilling fluid centrifuge treats the mud liquid, we reinject it into the mud circulation system. We transport the waste from the treatment to the cuttings box.

The drilling cuttings waste management system produced by Xi’an HL Petroleum is widely used in oil field drilling projects in Kuwait, Saudi Arabia, the United Arab Emirates, Kazakhstan, Algeria, Uzbekistan, etc. These oil field drilling companies have also given many good reviews to our drilling cuttings waste management system! In addition, we will also provide scientific and economical mud non-floating solutions for oil field drilling companies, which can effectively control the moisture content of drill cuttings in drilling mud (6%-10%), stabilize the liquid phase performance, and achieve the purpose of mud non-floating drying treatment. At the same time, the drilling cuttings waste management system can be customized according to customer needs and site conditions. So customers who have this need, please contact us quickly, and welcome all bosses to visit our factory.