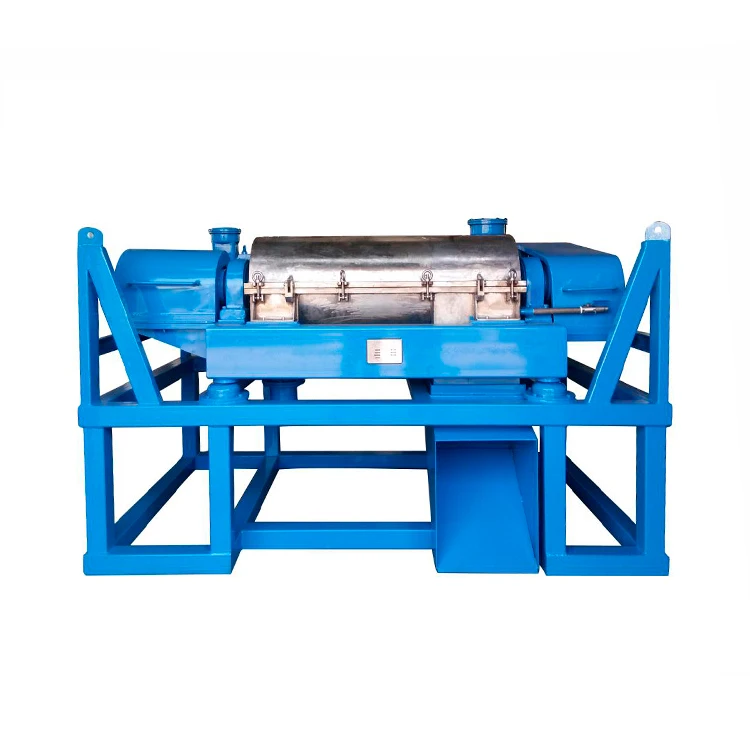

A drilling mud centrifuge is a five-stage solids control device within a drilling mud solids control system. This piece of equipment uses the principle of centrifugal sedimentation to separate suspended solids from drilling fluid. It not only balances the fluid’s viscosity and specific gravity but also recovers barite fines, which helps to reduce overall drilling costs.

The device is also a crucial part of solids control for environmentally friendly waste mud treatment. It excels at separating solids in the 2-5μm and 5-7μm range. This makes it essential equipment for oil drilling, coalbed methane drilling, and environmentally friendly waste mud treatment.

Drilling Mud Centrifuge Classification

Currently, drilling centrifuges can be divided into three types based on the separation factor:

Low-speed centrifuges: Also known as “barite recovery centrifuges,” they have a separation factor of 500-700 and a speed range of 1600-1800 rpm. They are primarily used for barite recovery.

Medium-speed centrifuges: They have a separation factor of approximately 800 and a speed range of 1800-2200 rpm. They remove harmful solids from mud and control mud density and viscosity. Drilling crews currently use them as their most common centrifuge.

High-speed centrifuges: They have a separation factor of approximately 1200-2100 and a speed range of 2200-3000 rpm or higher. They typically remove harmful solids from low-density drilling fluids and control mud viscosity. They often work in tandem with low-speed centrifuges to form a dual-unit system. This system effectively removes harmful solids while preventing excessive barite waste, and the drilling industry has widely recognized and adopted it both domestically and internationally.

Centrifuge Technical Parameters

| Model | LW355×1257-N | LW450×842-N | LW450×1000-N | LW500×1000-N | LW600×1000-N |

| Bowl Diameter(mm) | 355 | 450 | 450 | 500 | 600 |

| Bowl Length(mm) | 1257 | 842 | 1000 | 1000 | 1000 |

| Max. Capacity(m³/h) | 30 | 40 | 50 | 50 | 60 |

| Max Bowl Speed(rpm) | 3200 | 1800 | 2200 | 2500 | 1600 |

| Separation Factor | ≤2296 | ≤820 | ≤1218 | ≤1817 | ≤900 |

| Main Motor Power(KW) | 30 | 22 | 30 | 37 | 45 |

| Auxiliary Motor Power(KW) | 7.5 | 5.5 | 7.5 | 7.5 | 7.5 |

| Dimension:Lx Wx H(mm) | 3000×1500×1650 | 2370×1700×1800 | 2580×1700×1850 | 2660×1670×1760 | 3060×1870×1790 |

| Weight(kg) | 3300 | 2950 | 3300 | 3400 | 3500 |

Drilling Mud Centrifuge Principle

Drilling centrifuges are specialized equipment for solid-liquid separation. A drum inside them separates the solid and liquid phases in the mud, including ultrafine solid particles from the drilling fluid. Principle: A drilling centrifuge uses the high-speed rotation of its drum to drive the incoming mud into a high-speed rotation. The mud is flung against the drum wall, forming a liquid ring. Solid particles in this liquid ring, subjected to centrifugal forces hundreds or even thousands of times greater than their own gravity, overcome the resistance of the mud’s viscosity and rapidly settle onto the inner wall of the drum, forming a solid layer and the liquid forming a liquid layer. A centrifuge’s separation factor is the ratio of the centrifugal force acting on the solid particles in the liquid ring to their own gravity. A centrifuge with a high separation factor can separate finer particles from the mud.

Applications of Centrifuges

Centrifuges are particularly effective in non-weighted mud systems. They separate solids larger than 2μm, effectively addressing the problem of ultrafine, harmful solids that desanders and desilters cannot separate. Centrifuges can quickly restore drilling fluid properties such as specific gravity, providing a reliable and safe guarantee for efficient and scientific drilling. In weighted drilling fluids, centrifuges primarily control viscosity and separate ultrafine solid particles from colloids.

Contact Us

Sales: HL Solids Control

E-mail: [email protected]