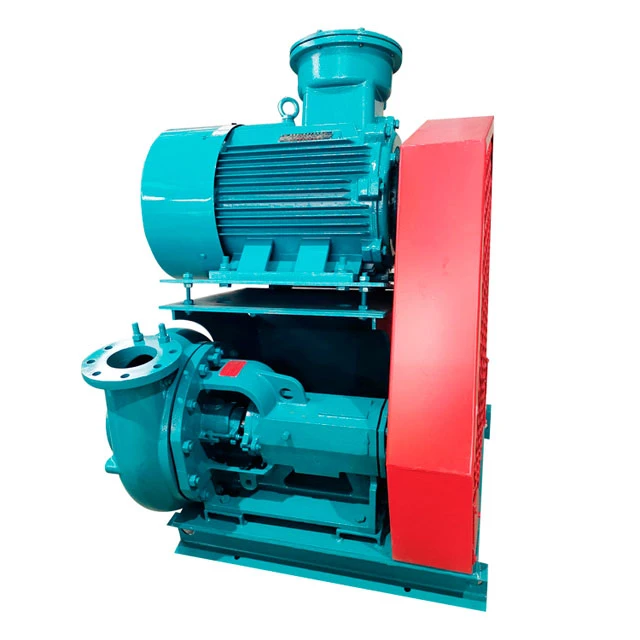

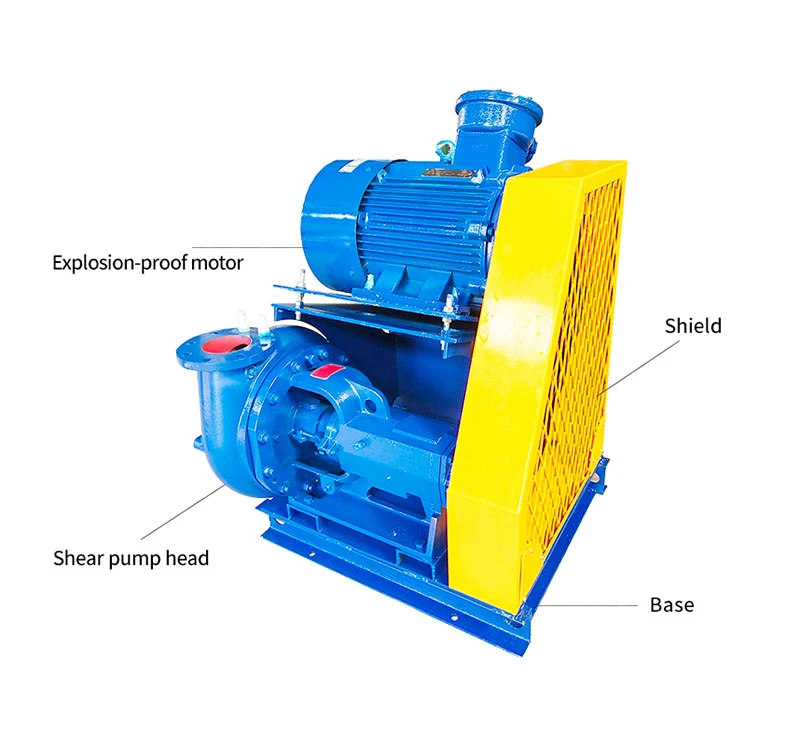

WJQ series drilling mud shear pump is a new type of equipment provided by HL Petroleum for users to quickly configure and process mud, which can meet the users’ mud configuration requirements. This series of shear pumps can effectively mix and fully hydrate the materials added to the drilling fluid, save the use of mud materials, shorten the time of mud configuration, and provide mud with good performance for the drilling process. This equipment can function as a shear flow, and can also serve as a slurry pump for desanders and desilters. Its main body and impeller are made of cast steel, which gives it a long service life and high performance.

Drilling Mud Shear Pump Technical Parameters

| Type | Capacity(m3/h) | Head(m) | Speed(rpm) | Efficiency(%) | Shaft power(KW) | Motor power(KW) |

| WJQ5×6J-75 | 150 | 30 | 2150 | 28 | 46 | 75 |

| WJQ5×6J-55 | 140 | 26 | 2050 | 28 | 35 | 55 |

| WJQ5×6J-45 | 105 | 24 | 1750 | 28 | 25 | 45 |

| WJQ5×6J-37 | 105 | 24 | 1750 | 28 | 25 | 37 |

Advantages of shear pumps

1. Shear pumps can greatly improve the hydration degree of soil moving particles.

The dispersion and hydration degree of soil moving particles in water depends on: electrolyte content in water, time, temperature, number and concentration of replaceable cations on the surface. Under the same other conditions, the use of shear pumps can save more than 30% of Pengrun soil.

2. Shear pumps can shear, dilute and hydrate polymers as quickly as possible.

The molecular weight of the polymers used in mud is relatively high, and it is not easy to hydrate directly. Therefore, pre-shearing is required for polymers. Shear pumps can provide high shear efficiency and accelerate the dilution and hydration process of polymers.

3. The displacement and head that shear pumps can provide can meet the requirements of preparing and processing mud.

Shear pumps are new equipment for providing rapid preparation and processing of mud, and users’ requirements for preparing high-performance mud.

Contact Us

Sales: HL

E-mail: [email protected]