The Mission 2500 Supreme Pump has a semi-open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The 2500 Supreme is available in hard iron, supreme hard iron, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Mission 2500 Supreme Pump Main Technical Parameters

| Type | Rotation speed (r/min) | Capacity (m3/h) | Pressure head/m | Efficiency (%) | Motor HP.(kw) |

| HCP3×2×13 | 1450/1750 | 40-60 | 24-35 | 65 | 7.5/11/15 |

| HCP4×3×13 | 1450/1750 | 60-80 | 26-33 | 65 | 11/15 |

| HCP5×4×14 | 1450/1750 | 120-150 | 28-33 | 65 | 22/30/37 |

| HCP6×5×14 | 1450/1750 | 180-240 | 26-33 | 65 | 37/45/55 |

| HCP6×5×11 | 1450/1750 | 160-170 | 24-26 | 65 | 30/37 |

| HCP8×6×14 | 1450/1750 | 240-260 | 33-35 | 65 | 55/75 |

| HCP8×6×11 | 1450/1750 | 220-240 | 24-26 | 65 | 37/45 |

| HCP10×8×14 | 1450/1750 | 280-320 | 33-38 | 65 | 75/90 |

Mission 2500 Supreme Pump Features

The Mission 2500 Supreme Pump boasts several key features designed for durability and efficiency:

1. Durable Casing Design: Its thick, rugged concentric casing includes replaceable gaskets, offering a longer lifespan compared to standard volute designs. This concentric approach reduces wear, making casing repairs more economical than full casing replacements.

2. Efficient Impeller: The wide, semi-open impeller minimizes axial thrust, which in turn enhances the casing’s performance. This design also helps consolidate solids behind the impeller, thus extending the life of both the mechanical seal and the lubrication box.

3. Protected Gaskets: The casing gaskets are recessed, providing them with additional protection.

4. Replaceable Case Cover: The pump features a replaceable case cover secured by dual sliding case bolts.

5. Versatile Case Options: Optional pump cases are available to accommodate both single and dual mechanical seal applications and can be set up with flushing lines.

6. Long-Lasting Seals: It includes non-adjustable mechanical seals built for extended life.

Mission 2500 Supreme Typical Applications

1. Barite, ferric oxide, and mineral oil

2. Base drilling muds

3. Glass fibers

4. Sugar processing

5. Ash or coal conveyers

6. Cement

7. Mine de-watering

8. Lime slurries

9. Kaolin clay

10. Crystalline forms

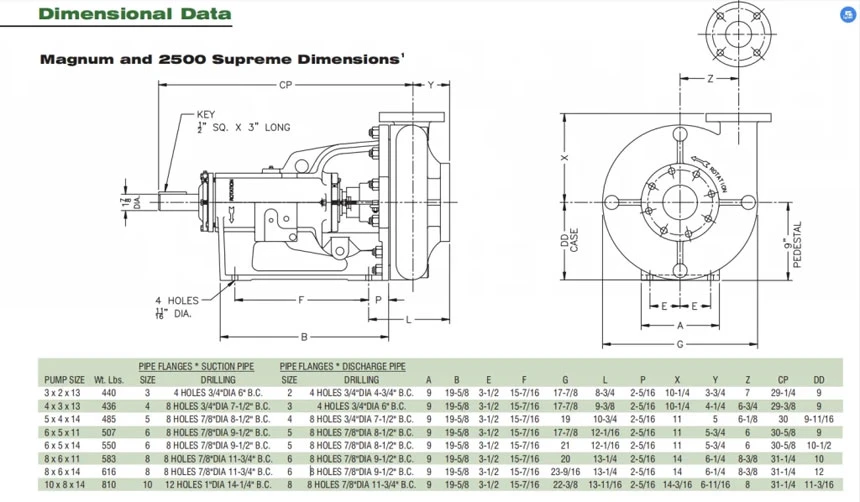

Dimensional Data