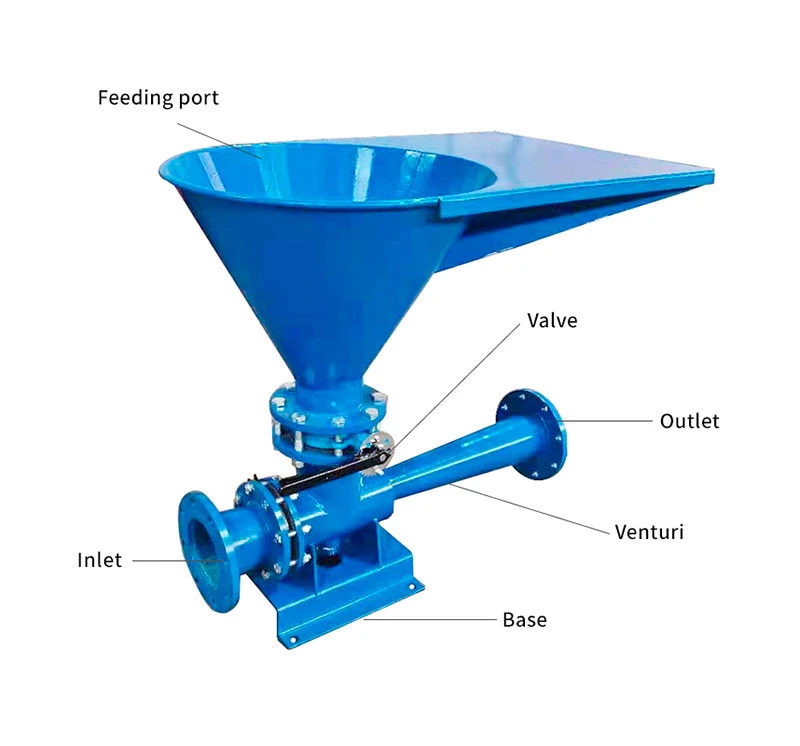

The mud mixer hopper is a mud mixing hopper designed using the Venturi principle. It is also called the Venturi jet mud hopper. Its main components include nozzles, mixing chambers, Venturi tubes, hoppers and butterfly valves. The Venturi tube is a hollow tube that gradually expands along a certain curved surface. Its main function is to increase the shear force of the liquid in the tube so that the material can be better dispersed and the pressure of the mixed liquid can be increased to enter the circulation tank.

The mud mixer hopper is just one of the many names for the hopper. The industry also calls it: feeding hopper, venturi hopper, jet mixing hopper, weighted hopper, etc. No matter what it is called, its function remains the same, which is to prepare the drilling fluid so that the drilling fluid performance meets the use requirements of the drilling site.

Mud Mixer Hopper Technical Parameters

| Model | HLD150 | HLD150-Y | HLD150-X |

| Capacity(m3/h) | 180 | 240 | 150 |

| Working pressure (Mpa) | 0.32-0.42 | 0.32-0.42 | 0.32-0.42 |

| Hopper diameter (mm) | 700 | 700 | 700 |

| Inlet diameter(mm) | 125/150 | 150 | 125 |

| Outlet diameter (mm) | 150 | 150 | 150 |

| Weight (kg) | 145 | 180 | 200 |

Operation of jet mixing hopper

Installation>>Get operation manual of jet hopper via [email protected]<<

A. After the jet hopper finish mixing, the pressure loss is very large. In order to make the drilling fluid mixed by the jet funnel be able to be directly discharged into the mud tank, the funnel is usually installed on the top of the mud tanks (i.e. high-position installation), and the mixed drilling fluid is directly discharged into the mud tank without climbing.

Once the jet hopper is installed at a high position, it is necessary to design a hoist or cantilever crane to lift the drilling fluid additives to the top of the mud tank.

B. When the jet hopper is installed at a low position, a reasonable climbing angle should be designed, and the outlet should be directly connected to the mud tank to prevent the drilling fluid from overflowing from the funnel.

The jet hopper is usually directly driven by an electric centrifugal pump to mix the mud. When the mixing effect is not good, it is necessary to adjust the distance between the jet hopper nozzle and the outlet end face to achieve the best mixing effect.