The drilling fluid solids control system mainly controls and separates the solids in the drilling fluid to achieve the recycling of the drilling fluid, also known as the mud purification system. This system plays a vital role in the oil drilling process, especially in the drilling of oil wells from 3,000 to 9,000 meters. The core principle of the solids control system is to use a variety of physical and chemical methods to remove solid particles in the drilling fluid, such as cuttings, mud and sand, to maintain the physical and chemical properties of the drilling fluid and ensure the smooth progress of the drilling operation.

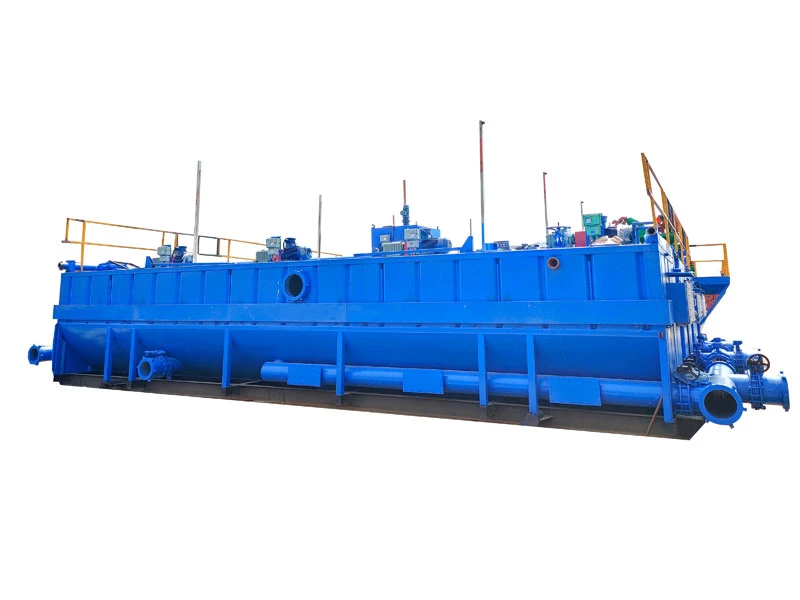

HL Petroleum designs and produces mud systems for oil and gas field drilling and work over projects. The HGK series solids control system produced by HL Petroleum mainly consists of a five-stage purification device including mud shakers, vacuum degasser, mud cleaner and centrifuge, and mud tanks, cooling water tank and supply tank. The system is equipped with various manifolds such as overhead pipelines (from the wellhead to the shale shaker), mud pump suction pipelines, weighted pump suction and discharge pipelines, clean water pipelines, medium-pressure mud gun pipelines, tank bottom connecting pipelines, etc.

Widely used drilling rigs and the supporting mud systems

| Rig Model | ZJ10 | ZJ20 | ZJ30 | ZJ40 | ZJ50 | ZJ70 | ZJ90 |

| Drilling Depth | 1000m | 2000m | 3000m | 4000m | 5000m | 7000m | 9000m |

| Mud Tank Capacity | >80m³ | >160m³ | >240m³ | >260m³ | >320m³ | >430m³ | >600m³ |

| Shale Shaker | >126m³/h | >180m³/h | >200m³/h | >240m³/h | >300m³/h | >360m³/h | >480m³/h |

| Degasser | / | >200m³/h | >200m³/h | >200m³/h | >270m³/h | >300m³/h | >360m³/h |

| Desander | >100m³/h | >180m³/h | >200m³/h | >200m³/h | >240m³/h | >300m³/h | >360m³/h |

| Desilter | >100m³/h | >180m³/h | >200m³/h | >200m³/h | >240m³/h | >300m³/h | >360m³/h |

| Medium Speed Centrifuge | / | >40m³/h | >40m³/h | >40m³/h | >40m³/h | >50m³/h | >60m³/h |

| High Speed Centrifuge | / | / | / | / | >40m³/h | >50m³/h | >60m³/h |

| Jet Mixer | >80m³/h | >120m³/h | >160m³/h | >180m³/h | >200m³/h | >240m³/h | >300m³/h |

| Shear mixer | / | >100m³/h | >100m³/h | >140m³/h | >140m³/h | >150m³/h | >150m³/h |

Note: The above content is for reference only.The final mud system depends on your on-site requirements.>>Send an Enquiry [email protected]<<

The following are some suggestion on the solid control system

* Drilling rigs below 2000m should be equipped with drilling fluid tanks, vibrating screens and mud mixing weighting device.

* Drilling rigs above 2000m (including 2000m) should be equipped with mud tanks, shale shakers, desanders, desilters and mixing weighting devices.

* According to the drilling process and drilling fluid system requirements, degasser, centrifuges, etc. can be equipped.

* Drilling rigs engaged in exploration wells, gas wells and oil wells with a gas-oil ratio of more than 300 should be equipped with degasser, centrifuges and shear pumps.

* Special operations (including hydrogen sulfide drilling and underbalanced drilling) should be equipped according to the actual drilling process requirements.

* Each mud tank should be equipped with corresponding mud agitators, mud guns and lighting systems according to the drilling process requirements.

Solids Control System Delivered Cases

Contact Us

Sales: HL

Phone/Wechat/WhatsApp: +86-17392256505

E-mail: [email protected]