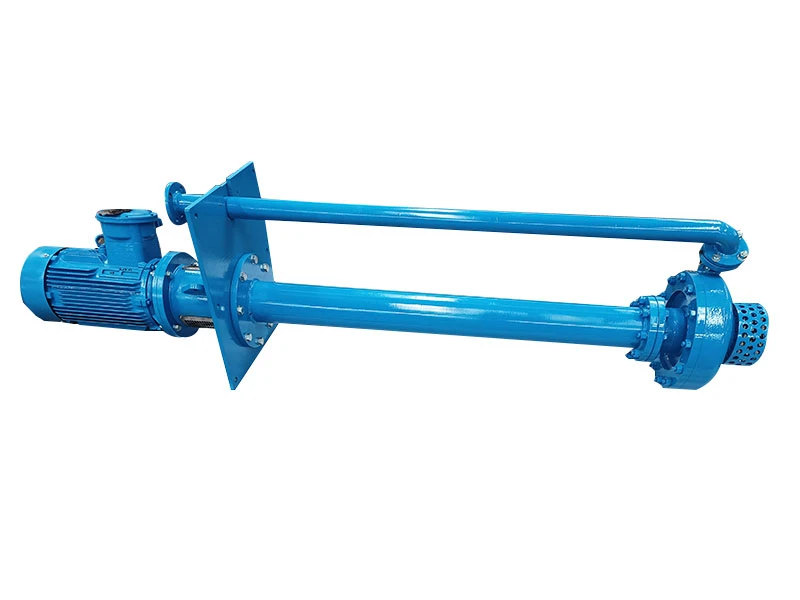

The YZ type vertical slurry pump features a single-casing structure, with the pump head submerged in liquid, eliminating the need for a shaft seal and resulting in a low failure rate. Its rational structural design enhances pump efficiency, making it suitable for conveying low-concentration materials. It boasts a long service life and low procurement cost.

Technical Parameters:

Flow rate range: 25~500 m³/h

Head range: 10~60 m

Flow-through component material: High-chromium alloy, A49, stainless steel

Submersion depth: Standard 1.2m (customizable)

Transmission method: Coupling drive

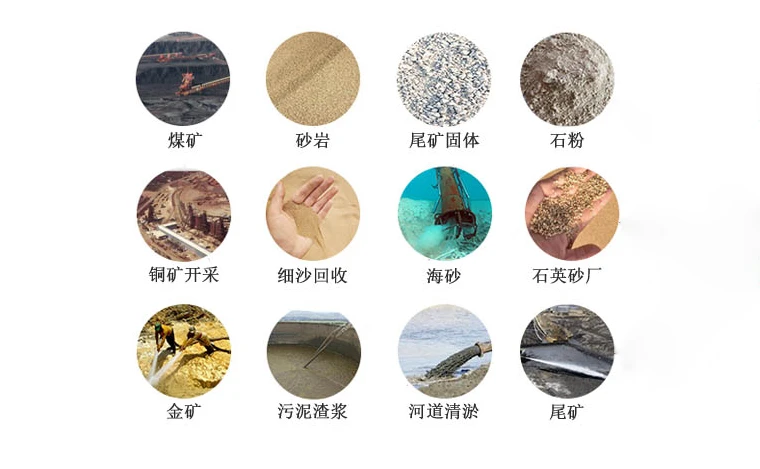

Application areas: Mining and beneficiation, power plant desulfurization, trenchless engineering, petrochemicals, environmental water treatment, coal preparation and washing, sand dredging, etc.

Based on the latest research results in fluid mechanics at home and abroad—the solid-liquid two-phase flow theory—our company developed and manufactured the YZ new centrifugal slurry pump and mud pump, which constitute a new generation of pump products. The YZ type slurry and sludge pumps utilize advanced domestic high-chromium alloy wear-resistant materials for their flow components. The unique single-channel open or double-channel impeller structure, coupled with a well-designed volute, enables the pump to effectively transport liquids containing solids, long fibers, or high viscosity. It offers advantages such as high efficiency, excellent flow characteristics, non-clogging, and anti-winding properties.

Based on the theories of SP and other slurry and sludge pumps, and through dedicated research by our technical staff, we have improved upon the shortcomings of traditional submersible pumps, such as the susceptibility to liquid ingress and bearing damage. This has resulted in a new type of submersible slurry and sludge pump. We optimized the product’s size and weight, making installation more convenient and flexible and keeping its performance reliable and stable.

To meet user needs, we have also developed various structural versions of this series of submersible slurry and sludge pumps, including extended and horizontal models, to maximize the satisfaction of our users.

Structural Features of Submersible Slurry Pumps:

1. This series adopts internationally advanced solid-liquid two-phase flow theory and is designed according to the principle of minimum loss. The geometry of its flow components conforms to the flow state of the medium, reducing eddies and impacts, as well as local and frictional hydraulic losses, thereby reducing wear on the flow components, increasing hydraulic efficiency, and reducing operating noise and vibration.

2. We make the flow components of this series of pumps from high-hardness, high-chromium alloy; this provides high wear, corrosion, and impact resistance, resulting in a long service life.

3. This series of slurry pumps features innovations in hydraulic and structural design. The flow components are made of a self-developed, wear-resistant, high-chromium alloy.

4. It features high efficiency, energy saving, long service life, light weight, reasonable structure, reliable operation, low vibration, low noise, and convenient maintenance.

Applicable Operating Conditions for Submersible Slurry Pumps: