Drilling fluids, often referred to as “drilling mud,” play a critical role in oil and gas exploration. They lubricate the drill bit, carry cuttings to the surface, stabilize the wellbore, and control formation pressures. However, improper management of waste drilling fluids can lead to significant environmental challenges, including soil and water contamination from chemicals, heavy metals, and hydrocarbons.

On average, drilling a single well generates substantial volumes of waste drilling fluid, contributing to operational costs and regulatory compliance burdens. Traditional disposal methods, such as landfilling or offshore discharge (where permitted), are increasingly restricted due to stricter environmental regulations worldwide.

Turning Waste into Opportunity: Economic and Environmental Advantages

Recycling drilling fluids offers a sustainable alternative that delivers both economic benefits and environmental protection. By removing harmful solids and reusing the cleaned fluid, operators can:

- Reduce the need for fresh drilling fluid purchases

- Minimize waste disposal expenses

- Lower transportation and handling costs

- Achieve compliance with environmental standards

- Extend fluid life for multiple wells

Industry studies and real-world applications demonstrate impressive returns. For instance, closed-loop systems and advanced solids control can cut drilling fluid costs by up to 50% and reduce waste volumes significantly. In one documented case, treating and recovering base oil from waste fluids yielded over $1 million in economic value while saving on storage and treatment costs.

Companies adopting recycling strategies report enhanced operational efficiency, reduced freshwater usage, and a smaller environmental footprint—aligning with global sustainability goals in the oil and gas sector.

Key to Effective Recycling: Advanced Solids Control Equipment

The cornerstone of successful drilling fluid recycling is efficient solid-phase removal. High-performance solids control equipment separates drill cuttings and low-gravity solids from the fluid, allowing it to be reused with minimal additives.

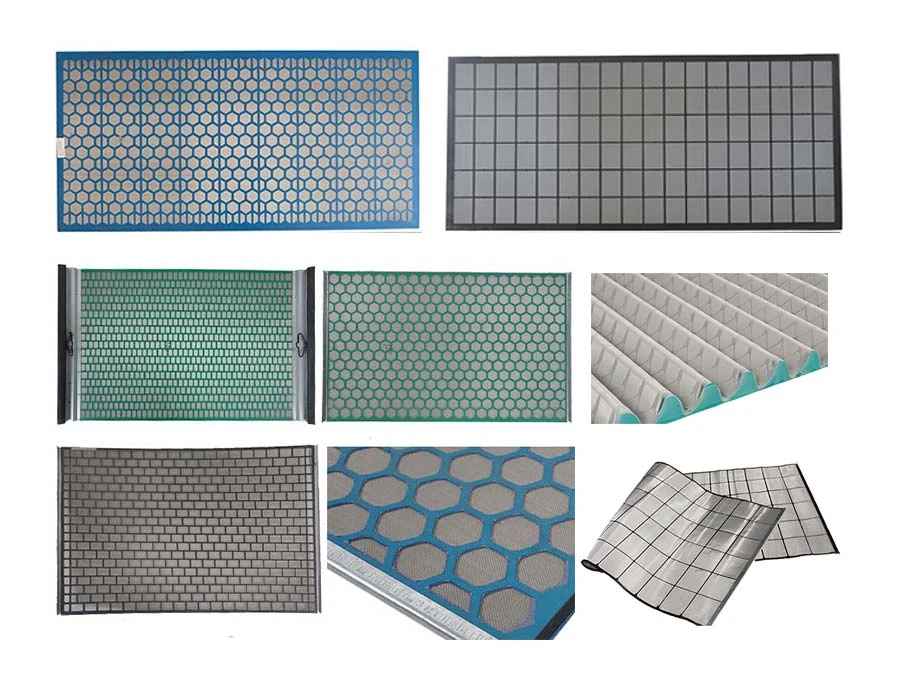

Xi’an HL Petroleum Equipment Co., Ltd. specializes in manufacturing professional solids control systems designed for reliability and efficiency. Our product lineup includes:

- Mud shale shakers

- Mud cleaners

- Desanders and desilters

- Decanter centrifuges

- Centrifugal pumps, shear pumps, and spray pumps

- Mud agitators, mud guns, and jet mud mixers

We also provide custom design, manufacturing, and accessories to meet specific project requirements. These systems enable thorough solid-liquid separation, maximizing fluid recovery and minimizing waste.

Partner with Us for Sustainable Drilling Solutions

At Xi’an HL Petroleum Equipment Co., Ltd., we are committed to supporting the oil and gas industry with innovative solids control solutions that promote drilling fluid recycling. By investing in our equipment, operators can achieve substantial cost savings, enhance environmental stewardship, and improve overall drilling performance.

Contact us today to discuss your needs and explore customized options. Welcome inquiries for quotes, technical consultations, or on-site support.

Xi’an HL Petroleum Equipment Co., Ltd. Email: [email protected] Website: www.solidscontrol.co

Embrace drilling fluid recycling—drive profitability while protecting the environment.