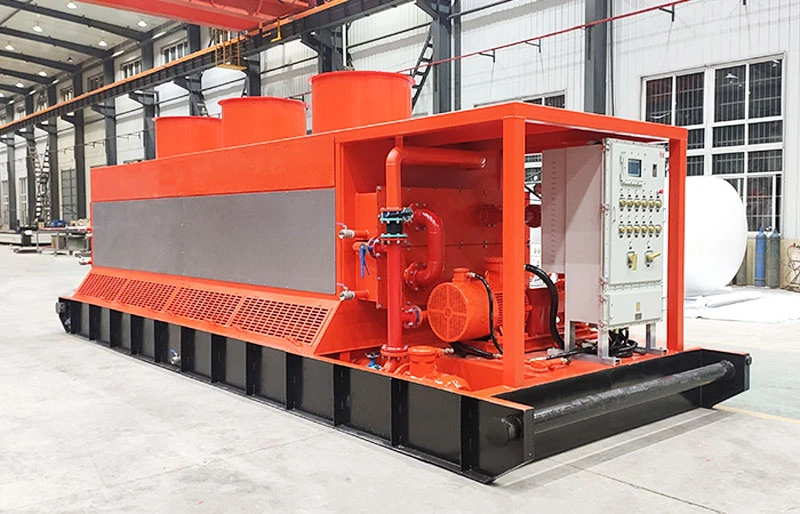

HL Petroleum recently passed inspection on its independently developed drilling cuttings equipment. This machinery is now set for shipment to a Middle East client.

The core system includes three high-G drying shakers and two cuttings dryers. These components are optimized for harsh, high-temperature, and high-sand conditions. This shipment highlights the strength of China’s high-end petroleum machinery in the global market.

As a key global oil and gas production region, the Middle East features complex and variable drilling environments, placing extremely high demands on the stability, efficiency, and environmental performance of drilling cuttings treatment equipment. The high-G drying shakers exported in this order are HL Petroleum’s flagship products, with the following key advantages:

Key Features of the High-G Drying Shaker:

The screen box undergoes overall heat treatment to release welding stress, enabling it to withstand high-intensity vibration conditions.

Screen installation uses a mechanical ratchet wrench for quick tightening, making disassembly and assembly convenient and highly durable.

Stainless steel forms the screen base frame support strips, offering strong corrosion resistance and extending their service life.

Aluminum alloy or stainless steel explosion-proof control boxes equip the electrical control system, providing excellent sealing and corrosion resistance.

Pre-tensioned screens for easy and rapid replacement.

Discharge modes support flexible switching between bottom and side discharge to accommodate various on-site installation needs.

Operators can adjust the screen box angle synchronously on both ends mechanically without stopping the machine, allowing the system to adapt to different processing volumes.

The two cuttings dryers work with drying shakers to form a complete treatment system. This system uses advanced solid-liquid separation to reduce oil content and meet Middle East environmental regulations.

By reusing the recovered drilling fluid, clients save resources and lower waste disposal costs. This approach achieves a win-win for both economic efficiency and environmental protection.

Key Features of the Cuttings Dryer:

Wide applicability, efficiently handling oil-based and composite-based drilling cuttings.

Equipped with a specialized high-pressure air knife for automatic screen basket cleaning, effectively preventing blockages.

We spray-weld the discharge scraper with a hard alloy to reach a hardness of HRC65, significantly extending its service life.

Standard configuration operates at 900 RPM, delivering a separation factor of up to 420G; optional variable frequency drive enables stepless speed adjustment.

This order from the Middle East fully reflects the client’s trust and recognition of HL Petroleum’s product quality and services. With 16 years of deep expertise in the petroleum machinery sector, HL Petroleum has always prioritized product quality as the company’s lifeline. From the selection of core components to final assembly, every step undergoes meticulous management and control. Our products have successfully obtained API international certification. To ensure perfect adaptation to the extreme operating conditions in the Middle East, our technical team conducted multiple rounds of rigorous performance tests and developed customized equipment protection solutions based on client requirements. These efforts guarantee that the equipment can be put into operation quickly upon arrival.

This successful export not only marks a further breakthrough for HL Petroleum in the high-end Middle East market but also adds a brilliant new chapter to the global outreach of Chinese petroleum equipment.