In the oil and gas drilling industry, selecting the right is crucial for efficient solids control, minimizing downtime, and optimizing operational costs. Shale shaker screens act as the first line of defense in separating drill cuttings from drilling fluid, ensuring the mud remains clean and reusable. This comprehensive guide delves into the materials science behind these screens, key selection criteria, and practical on-site decision-making strategies to help drilling engineers and operators make informed choices.

Understanding Shale Shaker Screens: The Basics

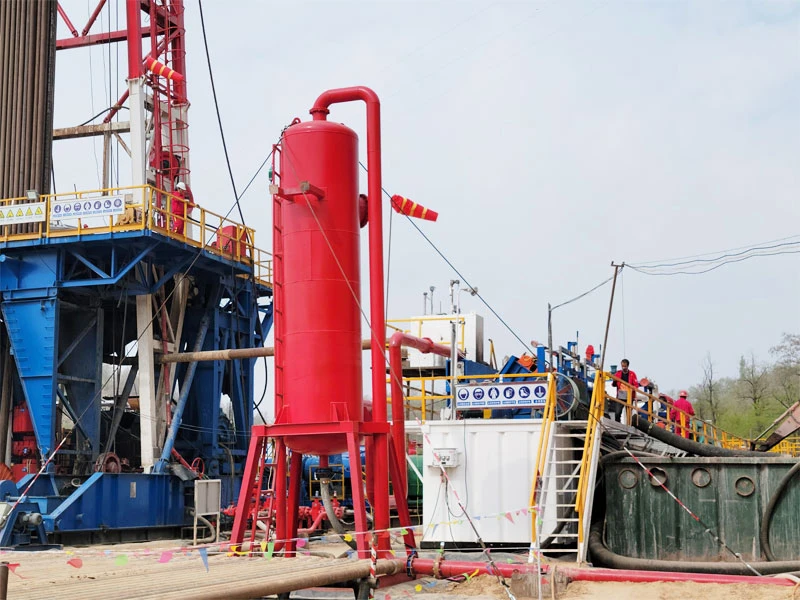

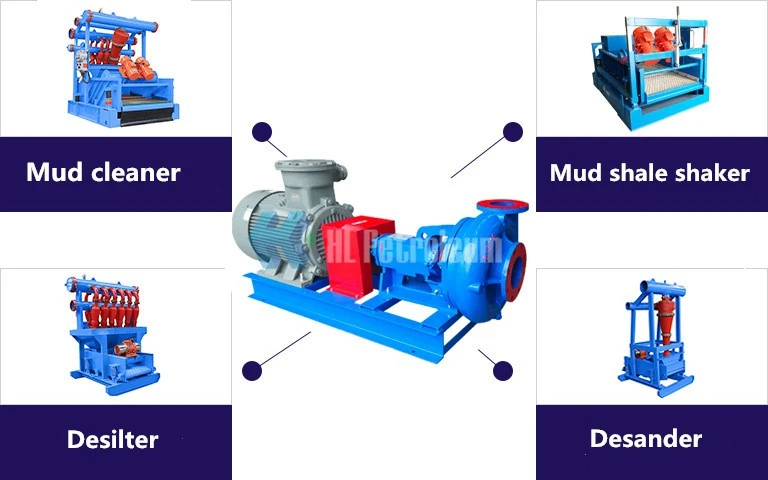

Shale shakers are vibrating sieves that remove large solids from drilling mud, preventing equipment damage and maintaining fluid properties. The screens themselves are the core component, typically consisting of layered wire mesh panels that vibrate to filter out particles. Proper selection directly impacts drilling efficiency, as improper screens can lead to mud losses, screen blinding, or inadequate solids removal.

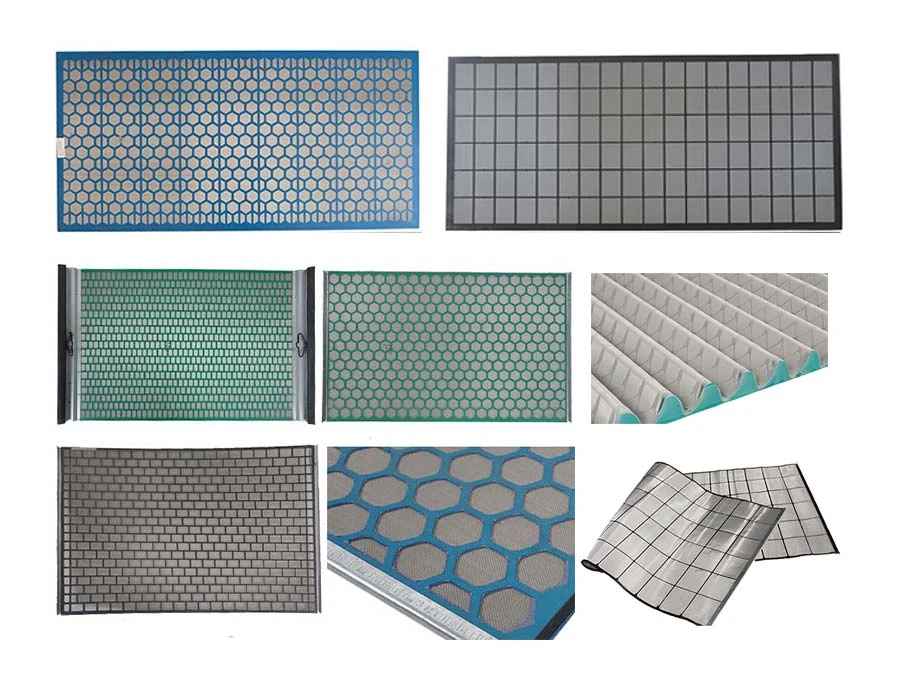

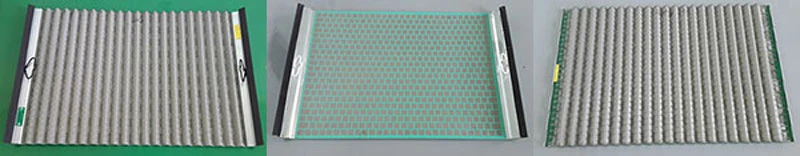

Common types include hook strip flat screens, pyramid screens, steel frame screens, and composite screens. Each type offers unique advantages in terms of durability, flow rate, and adaptability to drilling conditions.

For instance, pyramid screens provide increased surface area for better solids handling in high-volume operations.

Materials Science Breakdown: What Makes a High-Quality Shaker Screen?

From a materials science perspective, shale shaker screens must withstand harsh environments, including abrasive drill cuttings, corrosive chemicals in mud, and high temperatures. The primary materials used are stainless steel wire mesh, often in grades like 304 or 316 for superior corrosion resistance and mechanical strength. Stainless steel’s high tensile strength ensures the mesh can handle vibrational stresses without deforming, while its resistance to oxidation prevents rust in water-based or oil-based muds.

Composite screens, combining polyurethane or plastic frames with steel mesh, offer enhanced durability and lighter weight, reducing installation time and extending screen life. Polyurethane provides excellent abrasion resistance, making it ideal for aggressive drilling fluids. In contrast, traditional steel frames are robust but heavier, suitable for rigs requiring maximum structural integrity.

The layering—often two or three layers of mesh—enhances filtration efficiency; finer meshes capture smaller particles, while coarser backing layers provide support.

Key material properties to consider:

Tensile Strength: Ensures the screen withstands G-forces from vibration (typically 6-8 G’s in modern shakers).

Corrosion Resistance: Critical in saline or acidic muds; 316 stainless steel excels here due to its molybdenum content.

Abrasion Resistance: Polyurethane composites reduce wear from sand and shale particles.

Thermal Stability: Materials must handle temperatures up to 200°F without degrading.

By understanding these properties, operators can select screens that balance performance with longevity, potentially reducing replacement frequency by 20-30% in challenging wells.

Key Factors in Choosing Shale Shaker Screens

Selecting the optimal screen involves evaluating several technical parameters to match your drilling setup. Here’s a breakdown:

1. Mesh Size and API Designation

Mesh size determines the particle cut point—the smallest solids the screen can remove. API RP 13C standards classify screens by their D100 cut point (the size where 100% of particles are removed). For example, an API 200 screen has a finer mesh for capturing smaller particles, ideal for fine drilling in shale formations. Choose based on formation type: coarser meshes (API 40-80) for top-hole drilling with large cuttings, and finer ones (API 140-200) for deeper sections.

2. Screen Type and Design

Flat Screens: Simple and cost-effective for standard operations.

Pyramid Screens: Increased surface area improves conductance (fluid throughput), up to 50% higher than flat screens.

Frame Screens: Rigid support for high-vibration environments.

Composite Screens: Lightweight and repairable, reducing downtime.

3. Mud Properties and Drilling Conditions

Consider mud viscosity, density, and type (water-based vs. oil-based). High-viscosity muds require screens with higher conductance to prevent blinding. Environmental factors like temperature and corrosiveness also play a role—opt for corrosion-resistant materials in offshore rigs.

4. Cost and Longevity

While initial cost matters, focus on total cost of ownership. Durable screens may cost more upfront but last longer, cutting replacement expenses. Look for screens with non-blanked area percentages above 90% for better efficiency.

| Factor | Consideration | Recommended Choice |

| Mesh Size | Particle size in cuttings | API 80-120 for general use; finer for shale |

| Material | Corrosion and abrasion | Stainless steel 316 for harsh environments |

| Type | Flow rate needs | Pyramid for high-volume mud |

| Cost | Budget vs. durability | Composites for long-term savings |

On-Site Decision-Making Guide: Practical Steps for Rig Operators

On the rig floor, decisions must be quick and data-driven. Follow this step-by-step guide to select and optimize shaker screens:

1. Assess Current Conditions: Analyze mud samples for solids content, viscosity, and particle size distribution. Use laser particle analyzers if available to determine the dominant cut size.

2. Match Screen to Formation: In soft formations with fine sands, start with finer meshes. For hard rock with larger cuttings, use coarser screens to avoid fluid losses. Adjust based on ROP (rate of penetration)—higher ROP means more solids, requiring robust screens.

3. Monitor Performance: Install screens and observe for blinding (clogging) or sanding (excessive solids passage). If blinding occurs, switch to a coarser mesh or increase vibration intensity. For double-deck shakers, use a coarser top screen (e.g., API 50) and finer bottom (API 100) for layered filtration.

4. Adapt to Changes: Drilling phases vary—top-hole vs. production zones. Have a inventory of multiple mesh sizes and types. Quick-change designs in modern screens allow swaps in under 5 minutes.

5. Maintenance Tips: Regularly inspect for wear, clean with approved solvents, and rotate screens to even out usage. Track screen life metrics to predict replacements and avoid unexpected failures.

By following these guidelines, operators can maximize solids removal efficiency, potentially reducing mud dilution needs by 15-20% and extending equipment life.

Conclusion: Optimizing Your Drilling Operations

Choosing the right drilling mud shale shaker screens involves a blend of materials science knowledge and practical on-site evaluation. By prioritizing factors like mesh size, material durability, and mud compatibility, you can enhance drilling performance, cut costs, and ensure safer operations. For customized solutions, consult with solids control experts or suppliers specializing in API-certified screens. Investing in quality screens today pays dividends in efficient, sustainable drilling tomorrow.