In the raw material procurement process, you must select steel strictly according to GB/T 700-2006 standard to ensure mechanical properties, such as yield strength and tensile strength, meet the standards. You must select timber according to LY/T 1574-2016 standard to ensure the material is dry and free of obvious defects.

In the steel cutting process, we use a CNC flame cutting machine, controlling cutting accuracy within +0.5mm. By setting appropriate cutting parameters, such as oxygen pressure 0.5-0.7MPa and acetylene pressure 0.5-0.1MPa, we ensure a clean cut. For timber drying, a steam drying kiln controls the timber moisture content between 12% and 18%. This range effectively prevents future deformation and cracking. During the welding of steel components, we select welding rods suitable for the steel material. For example, we use E4303 for welding Q235 steel. We adjust the welding current according to the weld thickness, generally between 100-180A, to ensure the weld quality meets relevant standards. During the wood processing stage, precision wood milling machines mill the wood, controlling the milling depth and width error to within +0.1mm to achieve accurate dimensions and a smooth

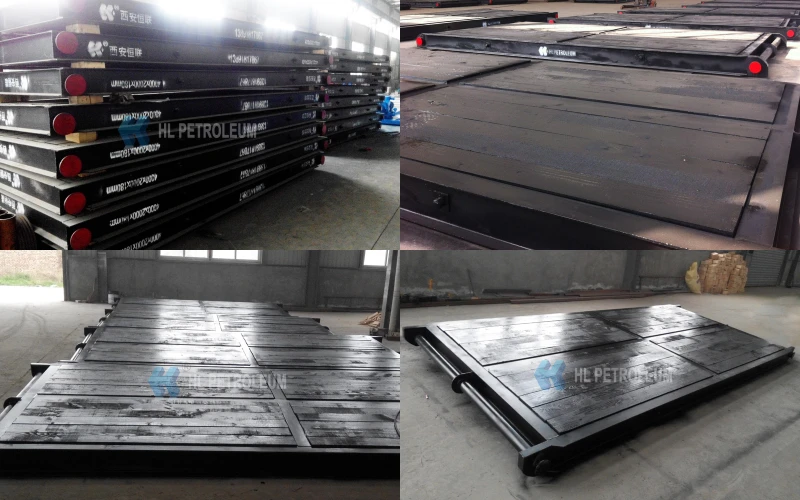

Raw material display for drilling rig mat processing:

In the steel-wood assembly stage, positioning fixtures ensure accurate alignment of steel and wood components. When using bolt connections, operators perform the bolt tightening torque according to the bolt specifications and relevant standards to ensure a secure connection. For surface pretreatment, the steel undergoes shot blasting to remove rust, thus achieving a rust removal grade of Sa2.5. This effectively removes oxide scale and rust, enhancing the adhesion of subsequent coatings. In the coating process, we select high-quality anti-corrosion paint and apply it according to the specified coating thickness requirements. Generally, the primer thickness measures 50-70µm, and the topcoat thickness measures 30-50mm, providing good anti-corrosion performance. During the quality inspection stage, we use non-destructive testing equipment to inspect welded areas for flaw detection. Simultaneously, we comprehensively inspect the dimensions and appearance of the steel-wood base to ensure the product meets design requirements.

Details of drilling rig mat processing:

In the finished product packaging process, plastic film and wooden pallets are used for packaging. The thickness of the plastic film is not less than 0.05mm, and the load-bearing capacity of the wooden pallets must meet the weight requirements of the product to prevent damage during transportation.

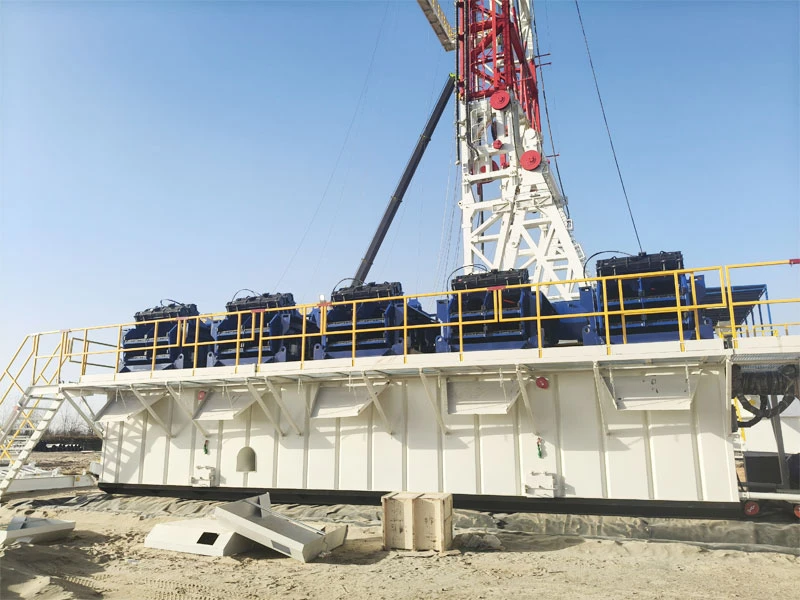

Finished drilling mat display:

Contact Us

Sales: HL Solids Control

E-mail: [email protected]