Mud agitators are crucial components of drilling mud solids control systems, widely used in activated sludge storage tanks to prevent suspended solids from settling to the tank bottom. As a manufacturer of solids control equipment, HL Petroleum offers mud agitators ranging from 4 to 30 horsepower, using FAG bearings and SOG oil seals. HL Petroleum’s mud agitators feature direct-coupled motors and gearboxes, resulting in a more compact design.

How to Choose the Right Agitator

To select the appropriate mud agitator, HL’s technical engineers will require the customer to provide the internal dimensions of the mud tank or pit so that our engineering team can recommend the appropriate agitator shaft length and impeller size. If the mud density is available, this will greatly assist in selecting the appropriate motor power. Generally speaking, higher mud density results in higher power.

How to Install a Mud Agitator

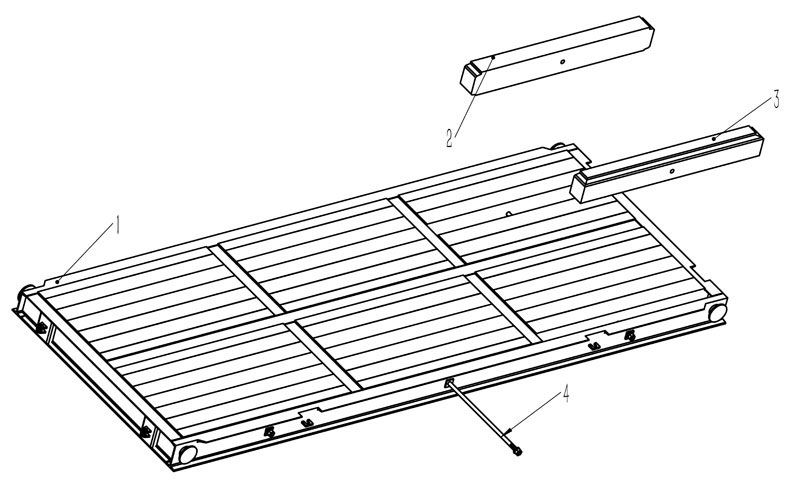

The gearbox and motor of mud agitators often sit on a skid plate. This design provides greater stability when installing the unit in the mud tank. HL delivers its mud agitator units separately. The skid plate, gearbox, and motor package as one set, and the shaft and impeller package as another. When installing the mud agitator on a mud tank, assemble the gearbox and motor and place them on the tank top, inserting the agitator shaft into the tank. Straight and vertical bolts connect the shaft to the gearbox. For shafts longer than 6 feet, the agitator uses a tank bottom stabilizer to prevent lower-end vibration during operation. HL Petroleum can provide agitators with one or two impellers, depending on the tank depth. The height from the tank bottom to the impeller determines the impeller’s position on the shaft. The recommended distance is 0.75 times the impeller diameter. For example, install a 20-inch impeller 15 inches above the bottom. The recommended blade height from the tank bottom is 5 inches. If dual impellers are required, install straight blades at the bottom, while install pitched blade impellers at a point approximately two-thirds of the distance from the tank bottom.

For more information about agitators, please contact us and we will provide you with detailed performance specifications and a quote. Thank you! [email protected]