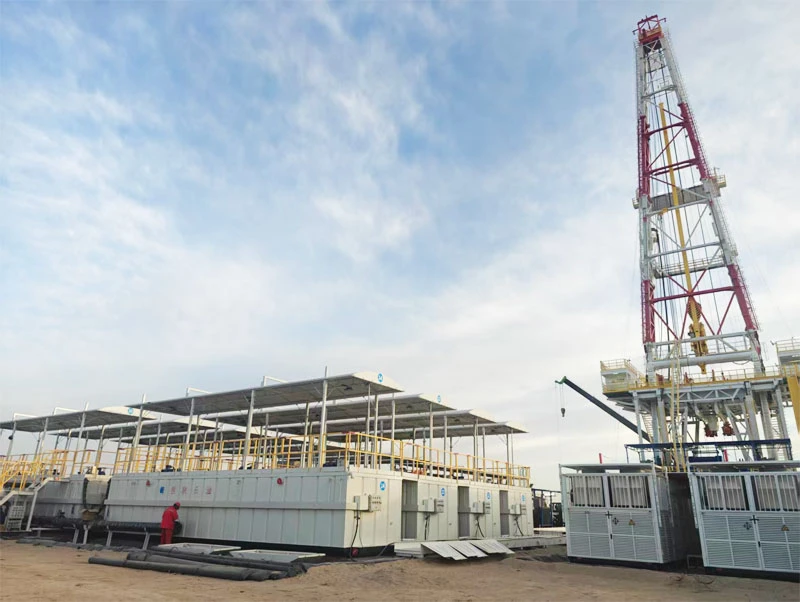

On-site use effect of mud gas separator

At the beginning of March, our company provided users with a batch of mud gas separators and ignition devices. Now they have been installed and passed the acceptance and officially put into use. Xi’an HL mud gas separator has good on-site use effect, high separation efficiency, and few faults. Users are very satisfied with our products.

A mud gas separator serves as one of the safety equipment items in oil field drilling, and it primarily works with an ignition device. The mud that comes out of drilling contains a large amount of harmful gas. The mud gas separator separates the mud from harmful gas. The harmful gas passes through the pipeline and connects to the electronic ignition device for direct combustion. This process simply and effectively treats the harmful gas in the mud coming out of drilling, and you can also recycle the mud.

Daily maintenance of mud gas separators:

1. When not in use, drain the mud gas separator of drilling fluid and rinse it with water. Never store mud in the separator body, as it can dry and prevent normal operation.

2. There are two main reasons for the short circuit of the mud gas separator:

a. The friction pressure of the natural gas discharged from the pipeline exceeds the hydrostatic pressure of the drilling fluid column;

b. A mud gas separator with a small diameter can’t separate gas from liquid fast enough. This forces incompletely separated liquid into the main circulation tank.

3. If the friction pressure of the natural gas discharged from the pipeline exceeds the hydrostatic pressure of the drilling fluid column, we can use the following methods to alleviate this problem.

a. Reduce the well-killing circulation displacement, that is, reduce the maximum flow of natural gas, and improve the working conditions of the separator. At present, this seems to be the most economical solution.

b. Increasing the height of the drilling fluid column can make the separator work more effectively, but the height of the drilling fluid column cannot exceed the height of the mud gas separator.

c. Reducing the number of elbows in the exhaust pipe and using elbows with smooth transitions can reduce exhaust friction resistance and improve the separation efficiency of the separator.

d. Increasing the inner diameter of the exhaust pipe is the most effective way to improve separation efficiency, although it is expensive.