The desilter processes the mud from the drilling process to remove silt particles and ensure the drilling fluid’s cleanliness. This improves drilling efficiency, protects the drilling equipment, and reduces the occurrence of failures.

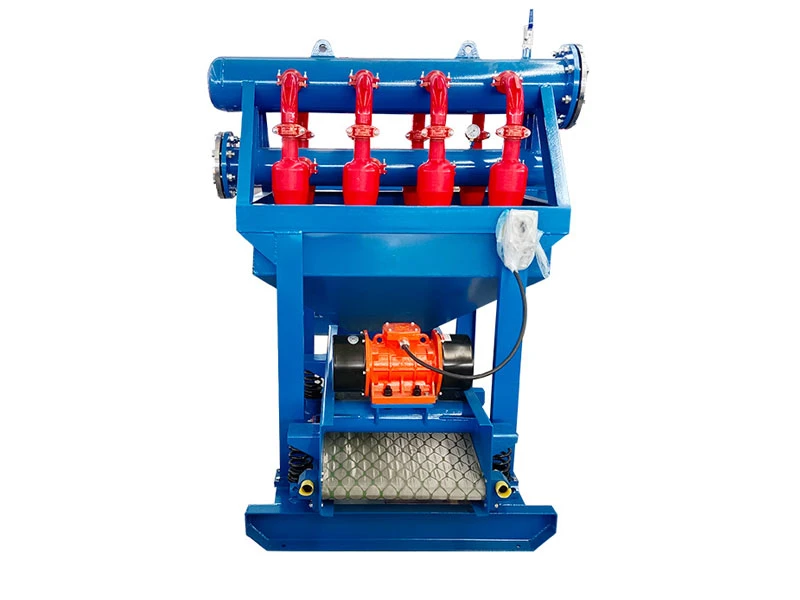

The mud desilter, a three-stage solids control device, operates within the drilling fluid’s solid phase control system. It combines a cyclone desilter and a shale shaker, and manufacturers can also supply it without the underflow screens according to customer requests.

The drilling fluid desilter usually use 4″ and 5″ cyclones, which is mainly used to separate solid particles with a particle size of 15-44 microns in the drilling fluid.

Technical parameters of desilter

| Model | HCN100x4S | HCN100xS | HCN100x10S | HCN100x16S |

| Capacity | 50 m3/h | 100 m3/h | 160 m3/h | 200 m3/h |

| Cyclone Diameter | 100mm(4″) | 100mm(4″) | 100mm(4″) | 100mm(4″) |

| Cyclone Quantity | 4 | 8 | 10 | 16 |

| Separation

Particle Size |

20~40μm | 20~40μm | 20~40μm | 20~40μm |

| Motor Power | 0.5 KW | 0.5 KW | 0.5 KW | 0.75 KW |

| Applicable Field | Wells less than 100 meters | Horizontal Directional Drilling | 4000m oil drilling | Oil drilling above 5000 meters |

| Supporting Sand Pump | SB4x3-15KW | SB5x4-22KW | SB8x6-55KW | SB8x6-55KW |

| Weight | 550KG | 750KG | 800KG | 1100KG |

| Dimension: LxWxH | 1500x800x1800 mm | 1500x1200x1800 mm | 1500x1300x1800 mm | 1500x1500x1800 mm |

Available products

Delivery

Contact Us

Sales: HL

E-mail: [email protected]