Product Introduction

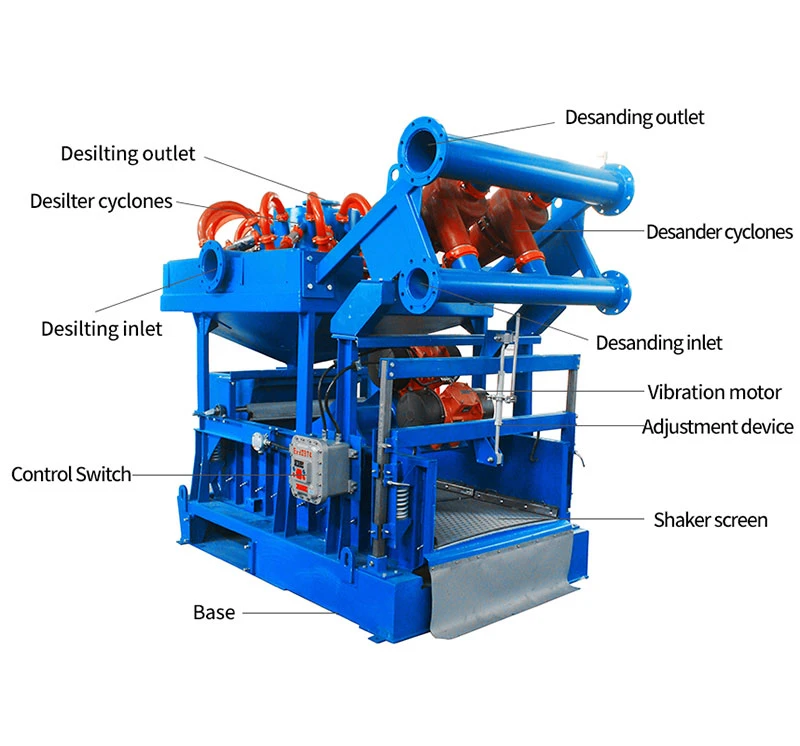

The drilling mud cleaner is used for desanding and desilting, serving as a secondary solids control device for drilling mud. This device integrates a desander cyclone, a desilter cyclone, and an underflow vibrating screen into a compact processing module, capable of removing harmful solids ranging from 20 to 74 μm from drilling fluid.

The drilling mud cleaner is a secondary and tertiary solids control device for drilling mud, combining a desander cyclone, a desilter cyclone, and an underflow vibrating screen into one. Its compact design, minimal footprint, and powerful functionality make it an ideal and efficient cleaning device for secondary and tertiary solids control in drilling mud.

The device features a modular design, with cyclones available in polyurethane, ceramic-lined, or rubber-lined materials. Quick-release clamps facilitate installation and removal. Capacities range from 120 to 360 cubic meters per hour. It features 4-inch (desilting) and 10-inch (sand removal) polyurethane cyclones, and the vibrating screens utilize either Martin or Oli brand vibrating motors. Its structure includes a sand separator, desilter, and funnel-shaped trough, enabling rapid filtration and safe reuse of drilling fluid.

Product Parameters

| Model | HQJ250-100×6 | HQJ300-100×8 | HQJ250×2-100×12 | HQJ300×2-100×16 | HQJ250×3-100×20 |

| Capacity | 80m³/h | 100m³/h | 160m³/h | 200m³/h | 240m³/h |

| Motor Power | 2×13KW | 2×13KW | 2×1.5KW | 2×2.2KW | 2×2.5KW |

| Vibration Ampitude | ≥5mm | ≥5mm | ≥5mm | ≥5mm | ≥5mm |

| Shale Shaker Screen | 2×1050×700mm | 2×1050×700mm | 3×1050×700mm | 4×1165×585mm | 5×1165×585mm |

| Size of Desander cone | 250mm(10”) | 300mm(12”) | 250mm(10”) | 300mm(12”) | 250mm(10”) |

| Quantity of Desander cone | 1 | 1 | 2 | 2 | 3 |

| Desander Separation Particle Sze | 40~100μm | 50~150μm | 40~100μm | 50~150μm | 40~100μm |

| Diameter of Desilter cones | 100mm(4″) | 100mm(4″) | 100mm(4″) | 100mm(4″) | 100mm(4”) |

| Quantity of desilter cyclones | 6 | 8 | 12 | 16 | 20 |

| Desilter Separation Particle Size | 15~44μm | 15~44μm | 15~44μm | 15~44μm | 15~44μm |

| Supporing centrifugal pump | SB4×3-15KW | SB5×4-22KW | SB6×5-37KW | SB8×6-55KW | SB8×6-75KW |

| Weight | 1800KG | 2000KG | 2800KG | 3100KG | 3500KG |

| Dimension:L×WxH | 2565×1920×2670mm | 2565×1920×2670mm | 2865×1920×2670mm | 3065×1920×2700mm | 3365×1920×2700mm |

Product Features

The drilling mud cleaner features a cyclone assembly consisting of 1-3 highly wear-resistant polyurethane desander cyclones and 8-16 highly wear-resistant polyurethane cyclones arranged in a combination. The overflow and feed pipes have large diameters and a small cone angle. The slurry redirection mechanism uses a tiltable metal trough fixed to the central axis to control the slurry flow direction. The circular arrangement of cyclones is used in conjunction with a rectangular recovery vibrating screen. These features enhance the mud treatment capacity and improve the efficiency of drill cuttings separation. It also features a simple structure, low cost, and is easy to move, install, and use.

Contact Us

Sales: HL Solids Control

E-mail: [email protected]