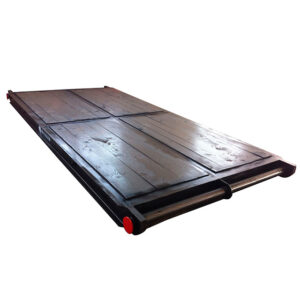

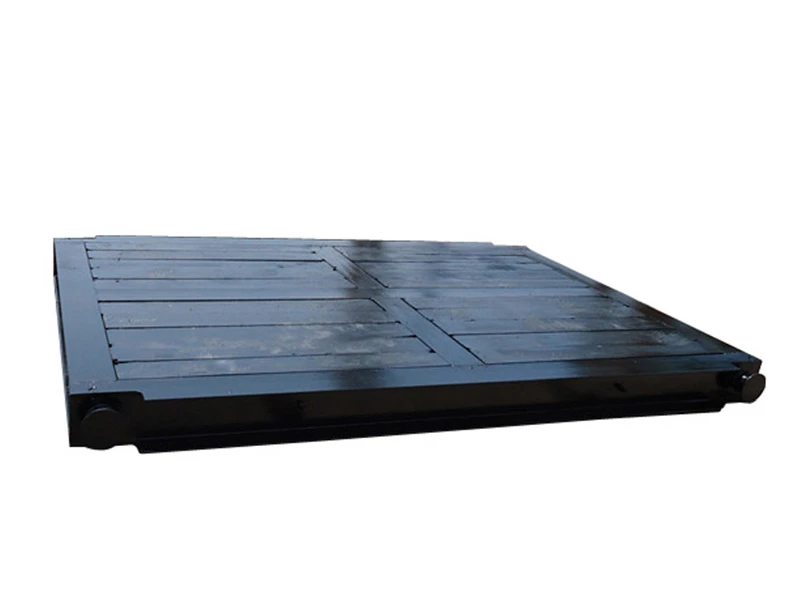

Drilling rig mats often find use in oilfield drilling. The rig mat possesses high strength, strong bearing capacity, and corrosion resistance. It suits ZJ20, ZJ30, ZJ40, ZJ50, ZJ70, and other types of drilling rigs in plains, deserts, beaches, swamps, and other areas with a drilling depth of 1000-7000m.

Drilling Rig Mats Technical Parameters

| Model | Length(mm) | Width(mm) | Height(mm) | Weight(kg) |

| HGM3220 | 3000 | 2000 | 200 | 1200 |

| HGM4220 | 4000 | 2000 | 200 | 1600 |

| HGM5220 | 5000 | 2000 | 200 | 2000 |

| HGM3218 | 3000 | 2000 | 180 | 1080 |

| HGM4218 | 4000 | 2000 | 180 | 1440 |

| HGM5218 | 5000 | 2000 | 180 | 1800 |

| HGM3218 | 3000 | 2000 | 160 | 960 |

| HGM4218 | 4000 | 2000 | 160 | 1280 |

| HGM5218 | 5000 | 2000 | 160 | 1600 |

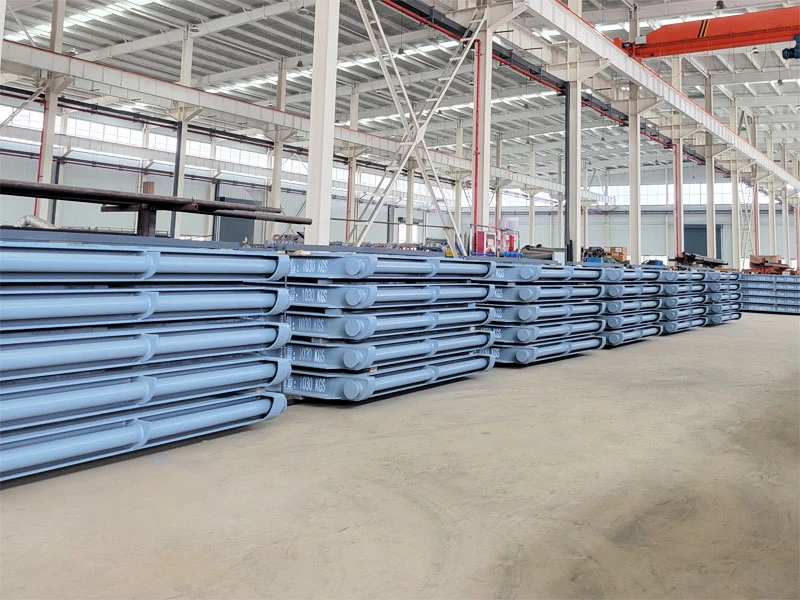

In addition, HL Petroleum produces drilling mattings of suitable size and thickness according to your requirements, spraying the paint you specify.>>Send an Enquiry [email protected]<

HGM Series Rig Mats Using Range

Suitable for ZJ20, ZJ30, ZJ40, ZJ50, ZJ70 each drill in drilling depth in the plains of 1000-7000 – m, plateaux, deserts, hills, beach, different areas, such as swamp.

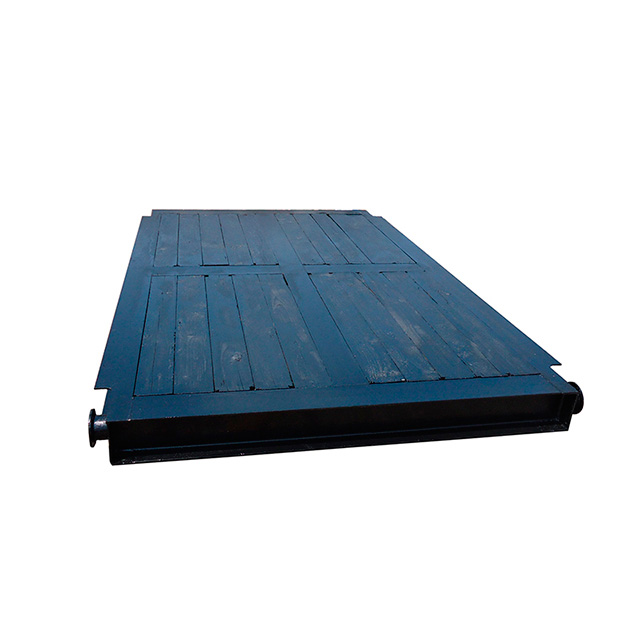

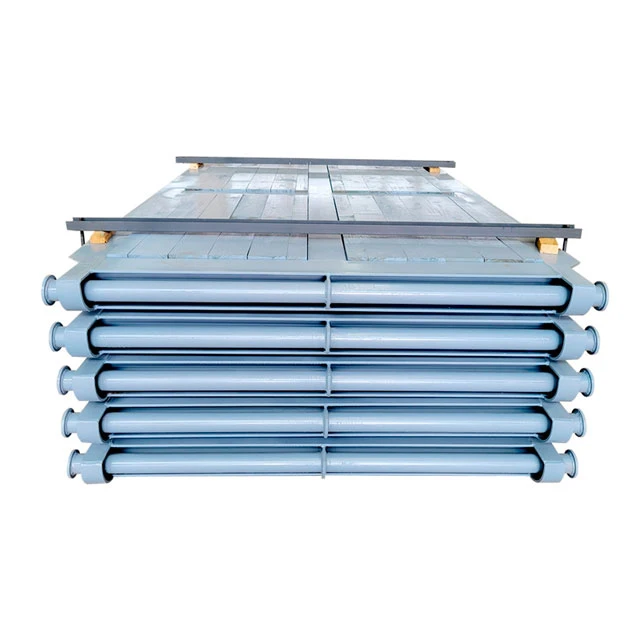

Rig Mats Features

The product has high strength, strong bearing capacity, good interchangeability, convenient transportation, low cost, convenient and quick installation, strong shock absorption, no cracking, no fear of water, corrosion resistance, no deformation, long service life, easy to recycle and store, etc. advantage.

What is the characteristic of HL Petroleum Drilling Rig Mats?

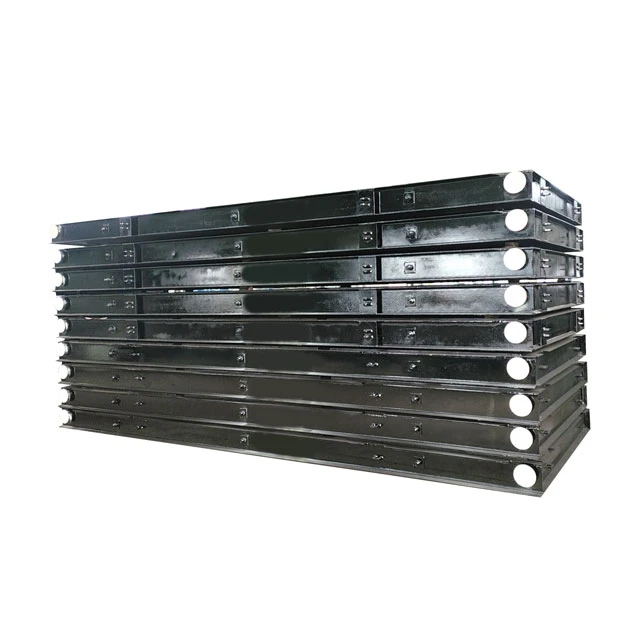

1. The matting is processed by embedding hard larch into the steel frame structure.

2. Timber is harder and more water-resistant than Korean pine.

3. According to the national standard GB9221-88 technology for railway sleeper timber anti-corrosion, we treat the precision-processed and designed square timber specifications with anti-corrosion treatment.

4. We make all steels from standard mould steel, and their pressure-bearing capacity and shock absorption capacity have reached the standards for use at the well site, which can completely replace the original concrete foundation structure.

5. Strong bearing capacity, high strength, strong shock absorption, no fear of water, no deformation, no cracking, corrosion resistance, good interchangeability, convenient transportation, low cost, convenient and fast installation, long service life, etc., and easy to recycle Storage, relocation of well team

6. The land can be directly replanted, and there is no problem that the land cannot be used after the well site is relocated.

7. HL Petroleum can design and produce steel and wood foundations of different specifications according to your requirements.

Contact Us

Sales: HL

E-mail: [email protected]