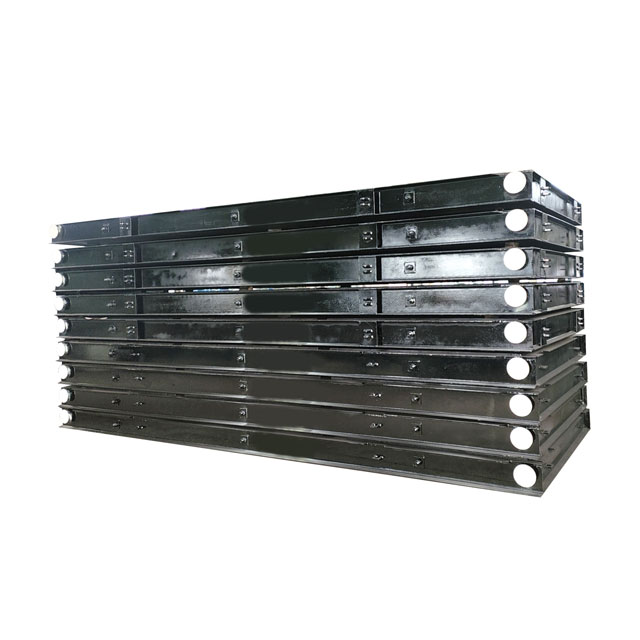

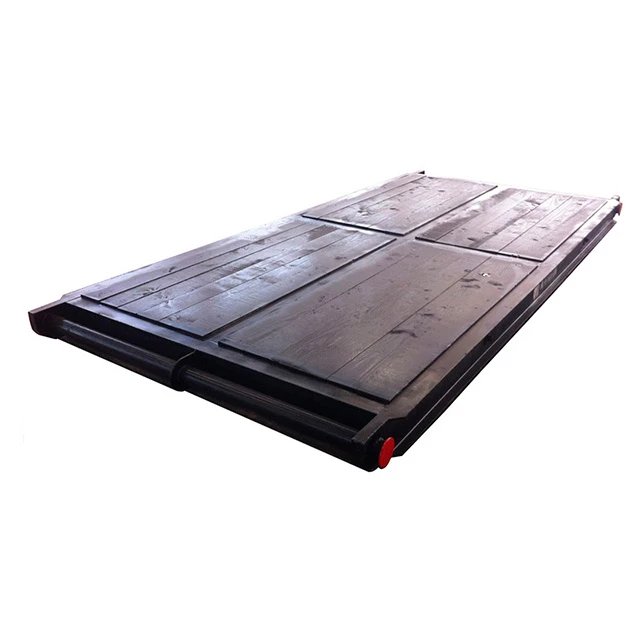

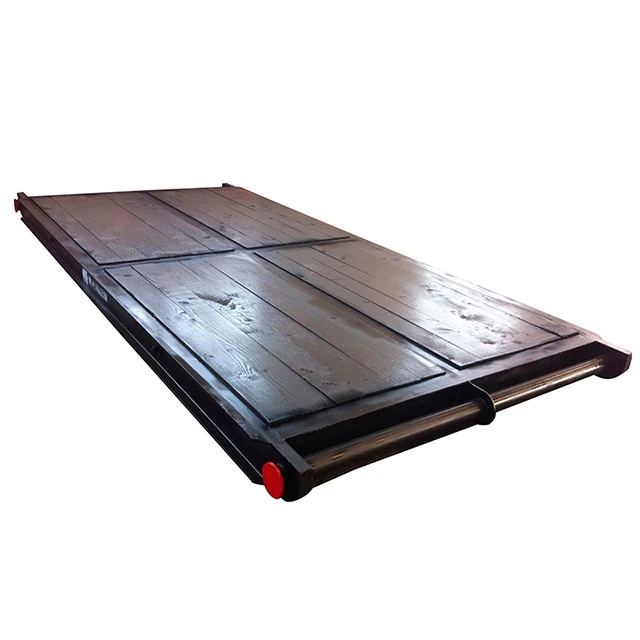

A matting boards drilling rig is a panel-like device composed of a steel frame and wood. A portable structural support platform, it is commonly used as a foundation for large equipment like oil drilling rigs and in oilfield drilling operations. Additionally, it can be used as a temporary road mat during field operations.

Matting Boards Drilling Rig Manufacturing Requirements

1. All steel materials are standard mold steel.

2. The embedded wood is made of hard, water-resistant larch. After being finely processed into square timber, it is treated with a corrosion-resistant process according to the national standard for railway sleeper wood corrosion protection, GB9221-88. The oil immersion depth is greater than 10mm, and the local compressive strength across the grain is greater than 40kg/cm². In addition, it is treated to prevent termites and insects.

Advantages of Matting Boards Drilling Rig

1. The rig mat offers high strength and load-bearing capacity.

2. Interchangeability is excellent, transportation is convenient, cost-effective, and installation is quick and easy.

3. It offers strong shock absorption, resistance to cracking, water resistance, corrosion resistance, deformation resistance, long service life, and easy recycling and storage.

4. The timber is made from larch, which is harder and more water-resistant than red pine. After being carefully processed into square timber, it is then treated with the anti-corrosion process specified in the national standard GB9221-88 for railway sleeper timber. The oil immersion depth is greater than 10mm, and the local compressive strength across the grain is greater than 40kg/cm².

5. All steel is standard mold steel.

The dimensions of the rig mat can be customized according to customer requirements.

Applications of Drilling Rig Pads

1. Used for drilling rigs operating at depths of 1,000-7,000m in various areas, including plains, hills, deserts, plateaus, beaches, and swamps.

2. Can be used as the foundation for drilling site equipment and facilities, such as barracks, oil tanks, water tanks, mud purification tanks, power plants, SRC rooms, MCC rooms, and mud pumps, ensuring their long-term stability.

The rig mat replaced the traditional concrete foundation, greatly reducing drilling costs and improving economic benefits. It not only saved land but also improved the level of on-site management.

Contact Us

Sales: HL Solids Control

E-mail: [email protected]