Mud agitators are crucial components of drilling fluid solids control systems. They agitate the drilling fluid inside the tanks to uniformly suspend useful solids. They also suspend harmful solids like drill cuttings, which allows a desander, desilter, and centrifuge to remove them. Useful solids, such as various weighting materials (hematite powder, barite powder) and a small amount of bentonite, also require suspension to maintain stable drilling fluid density and other properties.

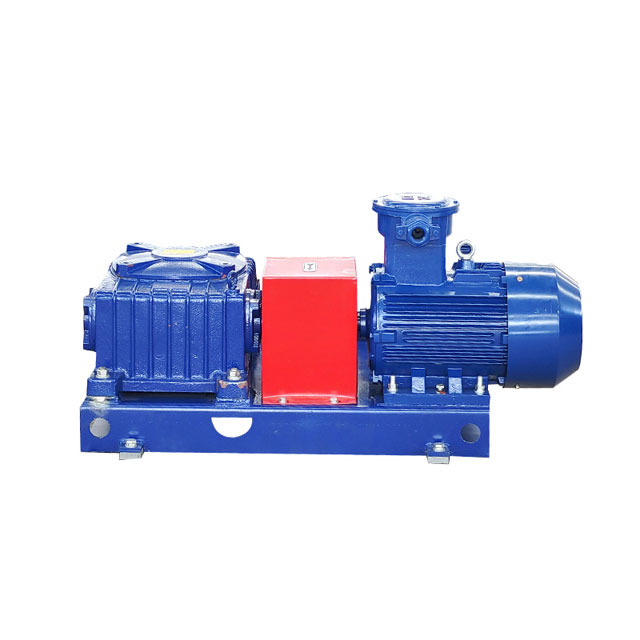

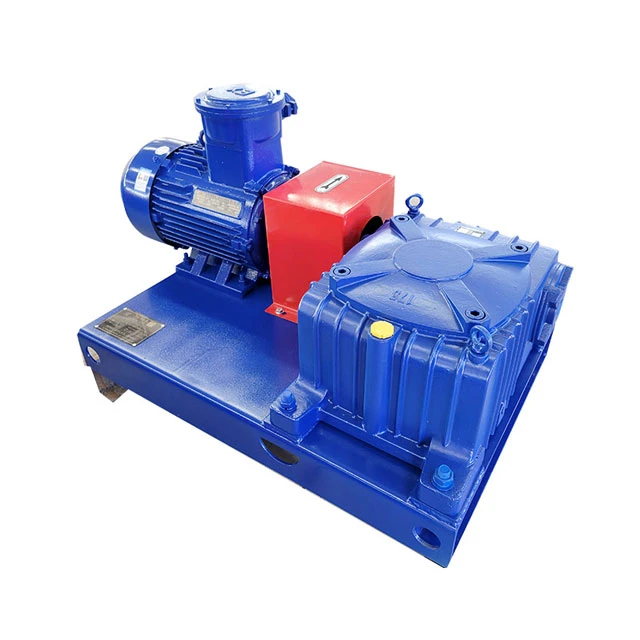

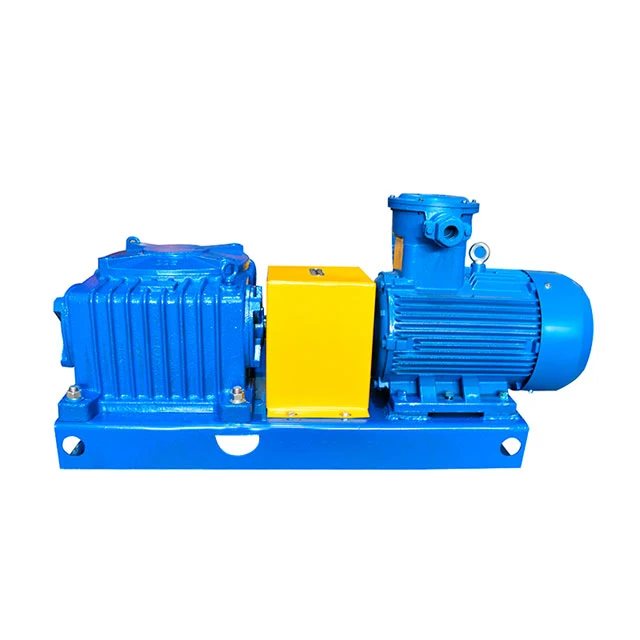

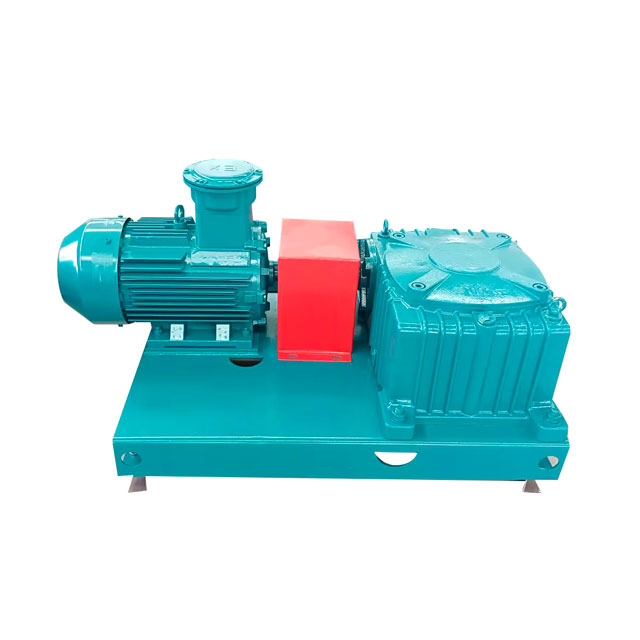

Features of the HJB Series Mud Agitators

a) Utilizes a worm/worm gear reducer; its compact structure, excellent meshing performance, and reliable operation.

b) Combining this reducer with an explosion-proof motor makes it suitable for operation in harsh field conditions.

c) The explosion-proof motor directly connects to the reducer input shaft using an elastic coupling instead of a belt drive, ensuring a constant speed for the impeller.

d) The stirring intensity is high, the spreading range is wide, and the structural design avoids the phenomenon of motor current overload at startup.

e) The horizontal placement of the explosion-proof motor makes installation, adjustment, or replacement very convenient.

Technical parameters of mud agitator

| Model | HJB5.5 | HJB7.5 | HJB11 | HJB15 | HJB18.5 |

| Motor Power(kW) | 5.5 | 7.5 | 11 | 15 | 18.5 |

| Impeller Speed(rpm) | 57 | 57 | 58 | 58 | 58 |

| Impeller Diameter(mm) | 800 | 850 | 900 | 1000 | 1200 |

| Dimension: L×W×H(mm) | 954*549*583 | 1101*664*623 | 1222*664*665 | 1334*734*685 | 1465*888*770 |

| Weight(kg) | 295 | 400 | 462 | 560 | 785 |

According to the type of reducer it matches, the agitator can be divided into:

(1) Belt drive agitator: the motor drives the agitator through a belt drive plus a bevel gear first-stage reduction;

(2) Worm drive agitator: the motor drives the agitator through a worm reducer;

(3) Gear drive agitator: the motor drives the agitator through a hard tooth surface two-stage or speed machine.

According to the installation form of the motor, the agitator can be divided into: horizontal agitator and vertical agitator

Working principle of mud agitator

The working principle of a mud agitator is that when the explosion-proof motor runs, it drives the reducer input shaft to rotate through an elastic coupling. The reducer then decelerates the motion and transmits it from the output shaft, which in turn drives the stirring impeller to rotate. When the blades of the impeller come into contact with the drilling fluid, they force it to produce a vortex motion, thereby preventing solid phase deposition and achieving the effect of uniform mixing of solid and liquid phases and consistent density.

Contact Us

Sales: HL Solids Control

E-mail: [email protected]