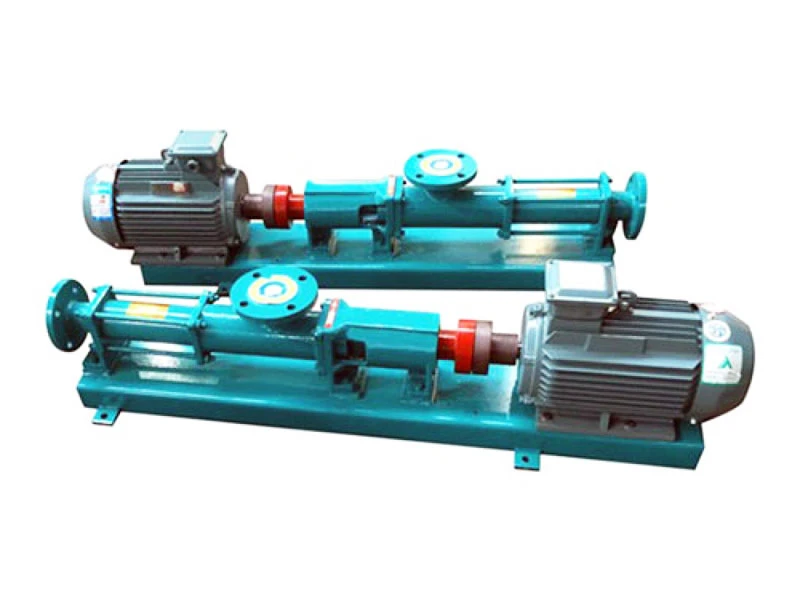

Screw pumps are ideal for feeding sedimentation centrifuges. Due to the special geometry of the two components, they form separate sealed cavities, allowing the mud to flow uniformly axially. The internal flow velocity is low, the volume remains constant, and the pressure is stable, thus preventing eddies and agitation. Each stage of the pump has an output pressure of 0.6 MPa and a head of 60 m (clean water), suitable for conveying media temperatures below 80℃ (up to 150℃ for special requirements). This screw pump can also be used for handling drilling waste and conveying drill cuttings from wet mud.

Screw Pump Features and Advantages

1. Stable Conveying Performance: Provides a uniform, continuous, and pulsation-free flow rate, ensuring stability during the conveying process.

2. High Adaptability: Adapts well to high-viscosity media, media containing solid particles, and corrosive media.

3. Low Shear Force: Minimal impact on the physical and chemical properties of the conveyed materials, particularly suitable for shear-sensitive materials.

4. Strong Self-Aspiration Capacity: Requires no additional filling equipment; can self-absorb liquid under a certain degree of vacuum.

5. Low Maintenance Costs: Relatively simple structure with few parts; easy replacement of vulnerable parts reduces maintenance and repair costs.

6. Good Sealing Performance: Effectively prevents leakage, ensuring a safe and clean working environment.

Screw Pump Technical Parameters

| Model | Speed(RPM) | Power(KW) | Inlet diameter | Outlet diameter |

| HG05-022B | 329 | 2.2 | DN50/2″ | DN50/2″ |

| HG10-040B | 243 | 4 | DN80/3″ | DN80/3″ |

| HG20-055B | 243 | 5.5 | DN80/3″ | DN80/3″ |

| HG30-075B | 243 | 7.5 | DN80/3″ | DN80/3″ |

| HG70-110B | 270 | 11 | DN125/5″ | DN125/5″ |

| HG90-185B | 229 | 18.5 | DN150/6″ | DN150/6″ |

Contact Us

Sales: HL Solids Control

E-mail: [email protected]