Shale shakers are the most fundamental equipment in the drilling fluid solids control system of the oil and gas industry. Their main application is to effectively separate solid particles (or mud) from drilling fluid during the drilling process. This process is crucial for maintaining the integrity and efficiency of the drilling fluid, preventing damage to downstream equipment, and ensuring safe and efficient operation.

HL Petroleum’s shale shakers are core equipment in the drilling fluid circulation system, undertaking the initial purification task. Shale shakers remove rock cuttings and large particles diameter 74μm, handling over 80% of the system’s total solid volume. Their performance is crucial; it directly affects the load on downstream equipment (desanders, centrifuges), ensuring drilling efficiency, reduced equipment wear, and cost control.

I. Shale Shaker Structure and Working Process

1. Shale Shaker Structure

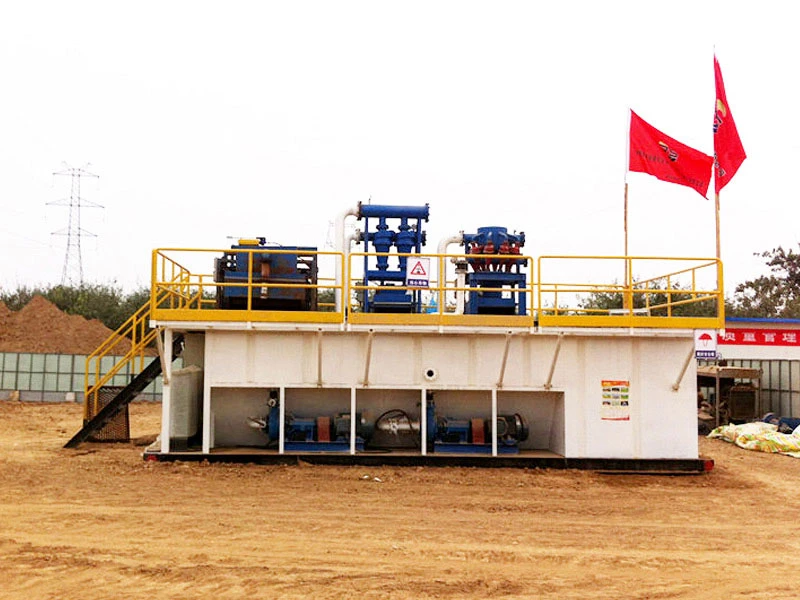

The drilling fluid shale shakers mainly consists of a base, screen box, screen mesh, excitation motor, damping springs, and control device.

2. Working Process

The first step in solids control is called primary solids removal. As the mud flows back to the wellbore from the drill string during circulation, it passes through a shale shaker that vibrates on the surface. Larger solid particles are separated from other cuttings by the different mesh sizes of the screen. Primary solids removal helps extend pump life and optimizes drilling time. This is achieved by minimizing downtime caused by abrasive solids damaging pumps or other equipment, such as mud tanks.

After the initial removal of large particles, some smaller particles (such as fine solids) may still remain in the mud used for drilling operations. At this stage, a smaller mesh screen is installed on the shale shaker to further refine this type of mud. By improving the fluid’s transparency and rheological properties, secondary solids removal helps reduce wellbore instability, stuck pipe, or poor wellbore cleanliness.

In addition, another function of the shale shaker is waste management during drilling operations. For example, in pitless drilling operations, many drilling rigs may operate simultaneously, spaced up to two miles apart; underground pipes or conduits connect all rigs, and each unit generates its own fluid, which flows into an open tank called a “pit.” Therefore, as it penetrates underground rock formations, core samples (such as chemicals used on-site) can further contaminate this fluid. Any given system will always retain some contaminants because, regardless of precautions, some leakage from fractures is inevitable; the key is how to effectively plug these leaks.

Finally, a balance between “high-efficiency separation” and “low energy consumption” is achieved by optimizing amplitude, frequency, and screen angle. For example, linear shale shakers have become the mainstream choice for drilling fluid solids control due to their regular screen surface movement, smooth chip removal, and the ability to use ultra-fine screens.

II. HL Shale Shaker Types

1. Dual-Track Shale Shaker

This screen uses two sets of excitation sources to freely switch between translational elliptical and linear trajectories. The translational elliptical trajectory is suitable for high-viscosity drilling fluids, increasing solids transport speed; the linear trajectory is suitable for handling large rock cuttings, reducing screen clogging. This series supports dual and triple-unit designs, with a single-unit processing area of up to 3.40 m² and a vibration intensity exceeding 6.5g.

2. Negative Pressure Shale Shaker

Combining vibration and negative pressure suction technology, this screen uses a single-channel pulsed vacuum system to reduce the probability of screen clogging, reducing the liquid content of rock cuttings by more than 30%. Its independently developed gas-liquid separation device can centrally process high-concentration, low-density mud, significantly reducing drilling fluid loss.

3. Double-Layer Shale Shaker

This screen adopts a double-layer screen design, increasing single-unit processing capacity by more than 50%, suitable for rapid drilling conditions. The hydraulic tilt angle adjustment range is -1° to +4°, dynamically optimizing the screening effect according to the characteristics of the rock cuttings.

III. Technology and Innovation

(I) Intelligent Control Technology

The automated control system integrates sensors (vibration acceleration, temperature), PLC, and variable frequency speed control modules, enabling real-time monitoring of the screen surface status and automatic parameter adjustment. For example, IoT technology facilitates remote diagnostics and predictive maintenance, reducing unplanned downtime. Henglian Petroleum’s dual-track vibrating screen also employs threaded anti-loosening technology to ensure reliable connections under vibration conditions.

HL Petroleum’s shale shaker is a benchmark product, featuring high-frequency vibration, multi-layer design, and intelligent control. Its high efficiency, durability, and environmental performance cut drilling costs, boost operational safety, and provide an innovative solution for the oil and gas industry.