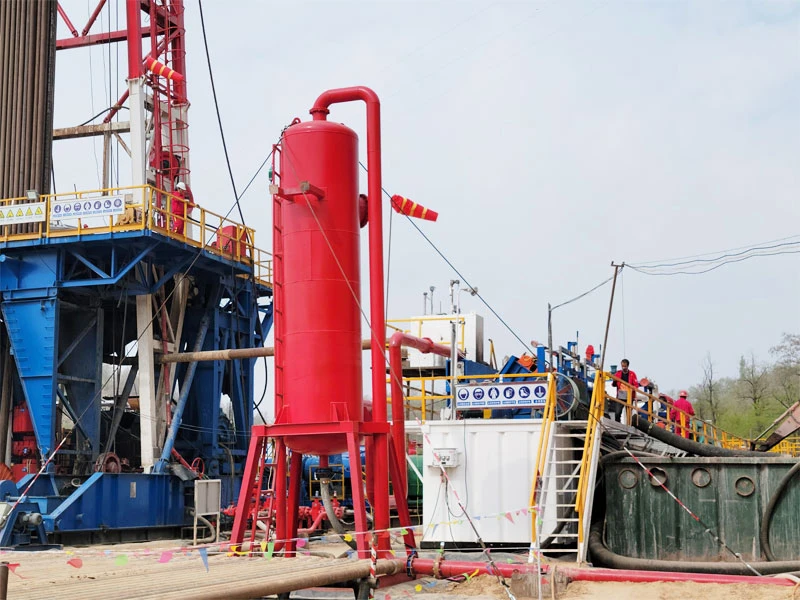

In the oil and gas drilling industry, maintaining clean drilling fluid (commonly known as drilling mud) is critical for efficient operations, equipment longevity, and overall wellbore stability. The oil drilling desander is a key component in the solids control system, designed to remove sand and larger solid particles from the drilling fluid. This hydrocyclone-based equipment plays a vital role in the second-stage solids removal process, ensuring optimal mud performance.

Key Components of the Oil Drilling Desander

The HCS desander is engineered for durability and high performance, consisting of the following primary components:

- Vibrating Screen (Mud Shale Shaker): Dewaters and further separates solids discharged from the hydrocyclones.

- Bracket and Support Structure: Provides stable mounting and structural integrity.

- Electric Control Box: Manages operational controls and safety features.

- Pressure Gauge: Monitors inlet pressure for optimal performance.

- Manifold: Distributes drilling fluid evenly to the hydrocyclones.

- Hydrocyclones (Cyclones): The core separation units that utilize centrifugal force to remove solids.

These components work together to deliver reliable solids control in demanding drilling environments.

How the Oil Drilling Desander Works

The desander operates through a efficient centrifugal separation process:

- A centrifugal pump delivers the drilling fluid containing solids (sand-water mixture) to the hydrocyclones under pressure.

- Inside the cyclones, centrifugal force concentrates finer sands, which are then directed to the vibrating screen via the underflow (grit chamber).

- The dewatering screen recovers materials with a solids concentration of 70%-85%.

- If the cleaning tank liquid level rises too high, excess fluid is safely discharged through the outlet port.

Adjustments for performance optimization include:

- Changing pump speed

- Modifying slurry properties

- Adjusting overflow rates

- Replacing sand nozzles

These tweaks enable the system to achieve three essential functions: cleaning, dehydration, and particle classification.

Hydrocyclone Design and Material Options

The hydrocyclone is the heart of the desander and typically features a three-part structure: volute (inlet section), cylindrical cone, and conical section.

Two primary material options are available to suit different operational needs:

1. High Wear-Resistant Polyurethane

- Advantages: Exceptional abrasion resistance, superior flow characteristics, and extended service life (up to 4200 hours).

- Limitations: Lower tolerance to high temperatures.

- Best For: Applications prioritizing longevity and efficient separation in moderate-temperature environments.

2. High-Chromium Cast Iron

- Composition: Includes stainless steel feed and discharge ports, conical ceramic liners, stainless steel conical tanks, and automatic/manual sand discharge and backflush valves.

- Advantages: Cost-effective, excellent high-temperature resistance.

- Limitations: Reduced wear resistance, shorter lifespan (typically requiring replacement every 2000 hours).

- Best For: High-temperature drilling operations where budget is a consideration.

Choosing the right material depends on factors such as drilling fluid temperature, abrasiveness of solids, and operational duration.

Benefits of Using HCS Desanders in Drilling Operations

- Enhanced Mud Quality: Removes particles typically in the 45-75 micron range, preventing equipment wear and improving drilling efficiency.

- Cost Savings: Reduces mud dilution needs and minimizes disposal costs.

- Reliability: Robust design ensures consistent performance in harsh oilfield conditions.

For high-quality HCS desanders tailored to your solids control requirements, contact our experts today. Our equipment is designed to meet API standards and deliver superior results in oil and gas drilling projects worldwide.