Considerations for Custom Rig Mats

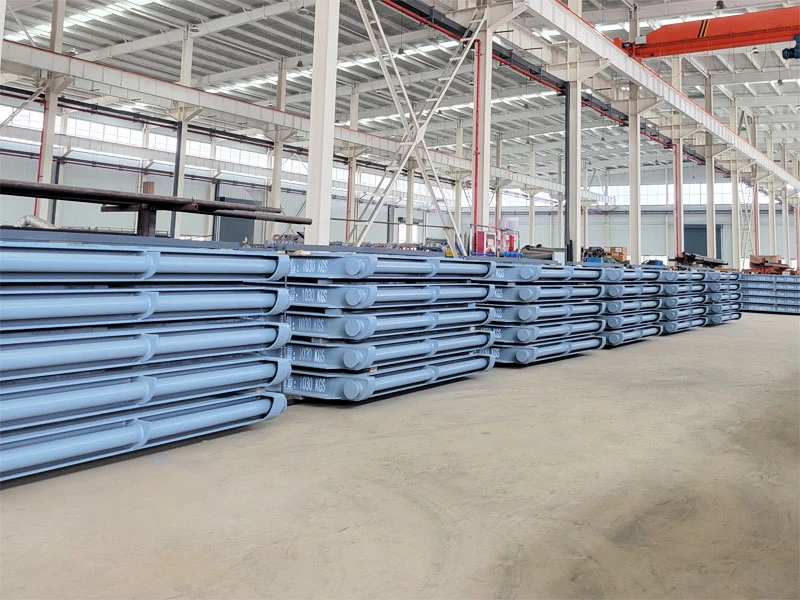

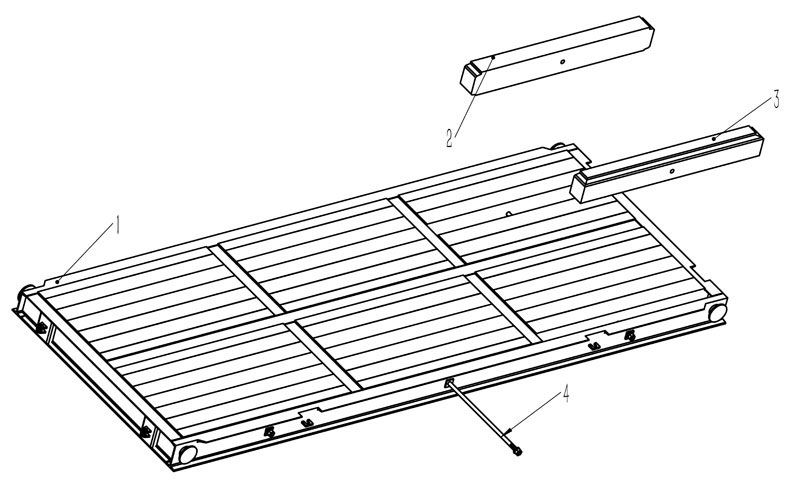

In the drilling industry, custom rig mats can provide optimal adaptability and effectiveness for your project. Whether it’s adapting to specific terrain conditions, providing additional support, or meeting specific size requirements, Xi’an HL Petroleum Equipment Co., Ltd. can meet your needs. This article will guide you through the steps and considerations involved in customizing rig […]

Considerations for Custom Rig Mats Read More »