How to choose the right mud cooling system? 7 key questions to help you achieve efficient cooling!

In industries like oil drilling, mining, and tunnel construction, mud cooling systems are crucial for ensuring stable equipment operation and improving operational efficiency. However, mud cooling requirements vary significantly under different operating conditions. How can you choose the right cooling solution? When communicating with customers, it’s important to address the following 7 key questions to ensure the system design precisely matches their specific needs.

1. Mud properties: Water-based, oil-based, or other media?

The type of mud directly influences the material selection and heat transfer method of the cooling system:

Water-based mud: Common, less corrosive, and generally uses conventional heat exchangers.

Oil-based mud: High viscosity, requiring consideration of explosion protection and specialized heat exchange structures.

Other media, such as synthetic-based mud, require specific design.

2. Mud handling capacity (m³/h)

The mud cooling system’s handling capacity must match the mud flow rate. Too little will result in insufficient cooling, while too much will increase costs.

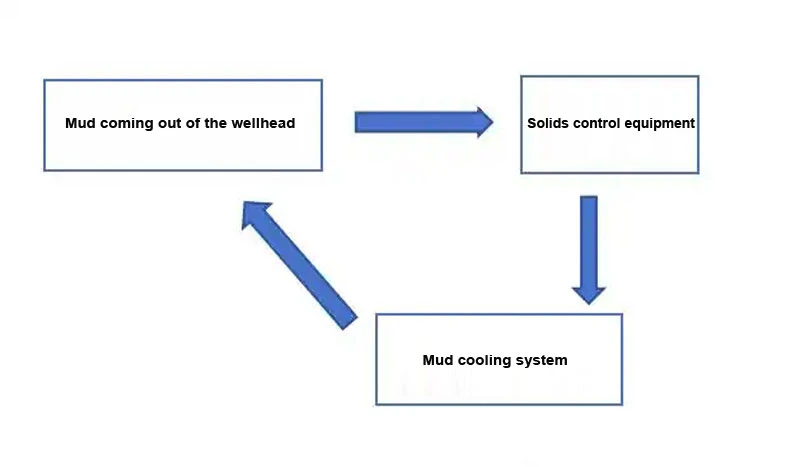

3. Cooling Range Requirement: Initial Temperature vs. Target Temperature

Initial Temperature: The temperature of the mud before it enters the cooling system (e.g., after entering the solids control system).

Target Temperature: The desired temperature after cooling.

For example, if the initial temperature is 60°C and the target temperature is reduced to 40°C, the cooling range is 20°C.

4. Mud Solids Content and Density

Solids Content (%): Affects mud fluidity and heat transfer efficiency. High solids content may require additional anti-clogging features.

Density (g/cm³): Affects pumping power and heat transfer calculations.

5. Cooling Source Type and Temperature

Most mud cooling systems use water as a cooling source, but different water sources can significantly impact the equipment:

Tap Water: Clean, non-scaling, and recommended.

Well Water/Lake Water/Sea Water: May contain impurities and require anti-scaling and anti-corrosion features.

Cold Source Temperature: Directly affects heat transfer efficiency and requires precise measurement.

6. Equipment Installation Environment

Ambient temperature and humidity (especially wet-bulb temperature) significantly impact cooling performance and must be clearly defined:

Installation location: Indoors, outdoors, on offshore platforms, in deserts, etc.

Extreme climates: High temperatures, high humidity, and high salt spray environments require special protection.

7. Customized Technical Solutions

Based on the above parameters, HL Petroleum’s technical team can calculate the heat load and select the appropriate heat exchanger (e.g., air-cooled, water-cooled, or a combination of air and water). We can also provide customized designs with anti-scaling, anti-corrosion, and explosion-proof features.