Shale shakers are key equipment in solids control systems and the first-stage processing equipment. Their performance directly affects the overall control effect of the system. During drilling, drilling fluid containing a large amount of drill cuttings is returned from the well. The role of the shale shaker is to separate the cuttings from the drilling fluid, allowing the cleaner drilling fluid to enter subsequent separation equipment.

1. Technological Characteristics of Drilling Fluid Shale Shakers

The technical level of a shale shaker is mainly reflected in its processing capacity (throughput and particle size separation), operational stability, lifespan, and operational flexibility. The processing capacity of a shale shaker is related to its structure, motion trajectory, vibration frequency, vibration intensity, screen area, and screen mesh coarseness. Modern shale shakers are generally high-speed, linear (or non-linear), fine-mesh, and multi-layered, playing a crucial role in solids control systems.

2. Working Principle of Drilling Fluid Shale Shaker

The shale shaker consists of a screen box, screen mesh, vibration springs, exciter, inlet pan, base, and support. The exciter’s rotation drives the screen box and screen mesh, creating a reasonable motion trajectory.Drilling fluid flows from the inlet pan onto the screen mesh. The screen box pushes solids out from the front. The liquid phase (with smaller solids) passes through the mesh into the drilling fluid tank, completing the separation.

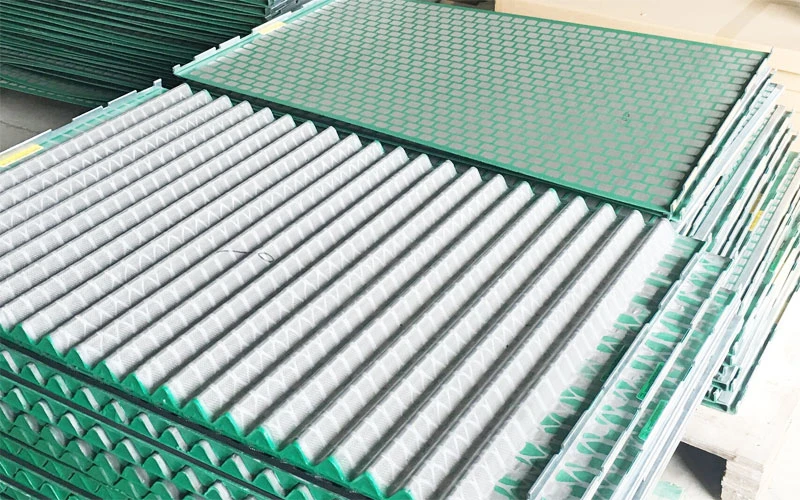

When selecting a shale shaker, an engineer must first select the appropriate screen mesh based on the size and particle size of the solid phase particles in the drilling fluid. They express the size of the holes on the screen mesh in “mesh.” The mesh number designates the number of holes per inch (in) of the screen mesh; the larger the mesh number, the smaller the holes. For example, API standards express a square mesh with 12 holes per inch as a 12-mesh screen (12×12).

The processing capacity is a very important parameter of a shale shaker. Besides the selection and determination of the motion parameters themselves, factors such as drilling fluid type, density, skin, size and amount of solid particles, and orifice size also affect this capacity. Therefore, operators need to give comprehensive consideration and make reasonable selections in actual use.

3. Types of Shale Shakers

1) Classification according to working principle

(1) Ordinary elliptical vibrating box: During operation, the screen box moves in a precise circular motion, and the center of mass can move in a pitching motion.

(2) Circular shale shaker: During operation, the screen box moves along a circular trajectory.

(3) Linear shale shaker: During operation, the screen box moves along a linear trajectory.

(4) Translational elliptical shale shaker: During operation, the screen box moves along a translational precise circular trajectory.

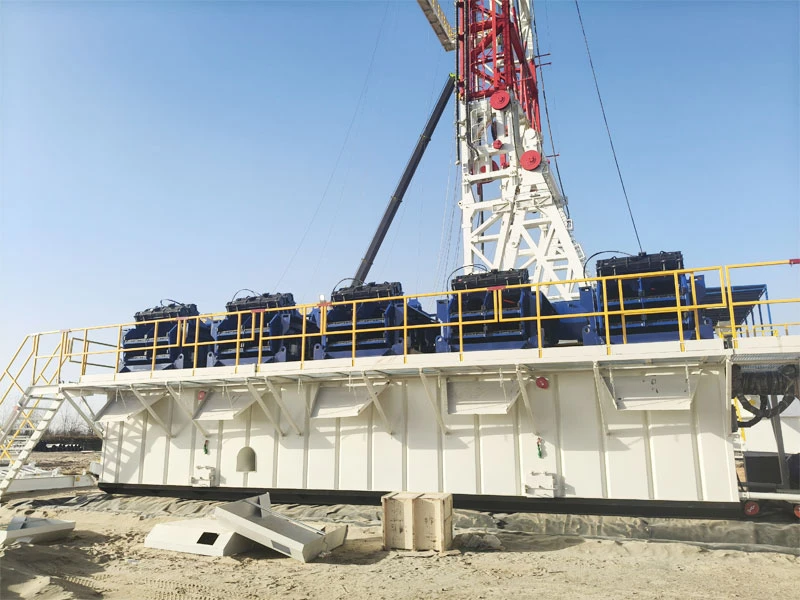

2) Classification according to structure

(1) Single screen: One shale shaker works independently.

(2) Double screen: Two shale shakers are installed side by side on the same base, which can process drilling fluid simultaneously.

(3) Multi-screen: Three or more shale shakers are installed side-by-side on the same base, allowing simultaneous processing of drilling fluid.

3) Classification by screen arrangement:

(1) Single-layer screen: The screen box has one screen surface.

(2) Double-layer screen: The screen box has two screen surfaces, one above the other, with a certain distance between them.

(3) Stacked screen: The screen box has two staggered screen surfaces.

4. Several commonly used shale shakers

1) Linear shale shaker

The vibrator of a linear shale shaker consists of two eccentric vibrators of equal mass rotating synchronously in opposite directions. This vibrator generates linear vibration, and the movement trajectory of the screen box is a straight line.

Compared to circular motion trajectory shale shakers, linear shale shakers have the following characteristics:

(1) Because the movement trajectory of the screen box is a straight line, the drill cuttings move regularly on the screen surface, resulting in smooth cuttings removal.

(2) Because the screen surface is horizontally placed, the overall height of the shale shaker is reduced.

(3) Due to the linear motion of the screen surface, the acceleration and force on the screen mesh are relatively uniform and maintain a constant direction. Therefore, ultrafine screens can be used on linear shale shakers, which is extremely important for drilling fluid solids control.

(4) The drilling fluid processing capacity of linear shale shakers is greater than that of circular shale shakers. Generally, under the same conditions, linear screens have a processing capacity 20% to 30% greater than circular screens. Looking at the development trend of drilling fluid shale shakers abroad, most solids control equipment manufacturers produce linear screens, but some companies are also developing elliptical shale shakers.

2) Elliptical Shale Shaker

Engineers developed the elliptical vibrating screen, also known as the balanced elliptical shale shaker, as a new type of shale shaker in the early 1980s. Products imported from abroad are already available in China. The balanced elliptical shale shaker combines the advantages of linear and circular screens; that is, the “major axis” of the ellipse enhances the drilling fluid transport component, while the minor axis reduces the possibility of some drilling fluid clogging the end holes.

3) Circular Shale Shaker

The circular vibrating box is equipped with a rotating acceleration vector device, which easily disperses drilling fluid on the screen surface, reducing the possibility of screen clogging. However, the circular motion and throwing angle are steep, resulting in a lower material conveying speed, and therefore, under the same conditions, the throughput is not as good as that of a linear screen.