In the oil and gas drilling industry, effective solids control and waste management are critical for operational efficiency, cost reduction, and environmental compliance. These processes involve removing drilled solids from drilling fluids (mud) while minimizing waste generation and ensuring proper disposal or recycling. By maintaining clean drilling fluids, operators can extend mud life, reduce downtime, and protect equipment from abrasion.

At HL Petroleum, we specialize in manufacturing high-quality solids control equipment designed to optimize these processes for drilling operations worldwide.

The Importance of Solids Control in Drilling Operations

Solids control refers to the mechanical separation of drilled cuttings and other solids from the drilling fluid. Uncontrolled solids accumulation can degrade mud properties, increase viscosity, cause equipment wear, and lead to issues like stuck pipe or lost circulation.

Key benefits include:

- Cost Savings: Reusing cleaned drilling fluid reduces the need for new mud and minimizes disposal expenses.

- Improved Drilling Performance: Cleaner mud enhances rate of penetration (ROP) and borehole stability.

- Environmental Protection: Efficient solids removal lowers waste volumes and supports regulatory compliance.

- Equipment Longevity: Removing abrasive solids prevents damage to pumps, bits, and other components.

Proper solids control is essential for both onshore and offshore drilling, helping operators achieve sustainable and efficient projects.

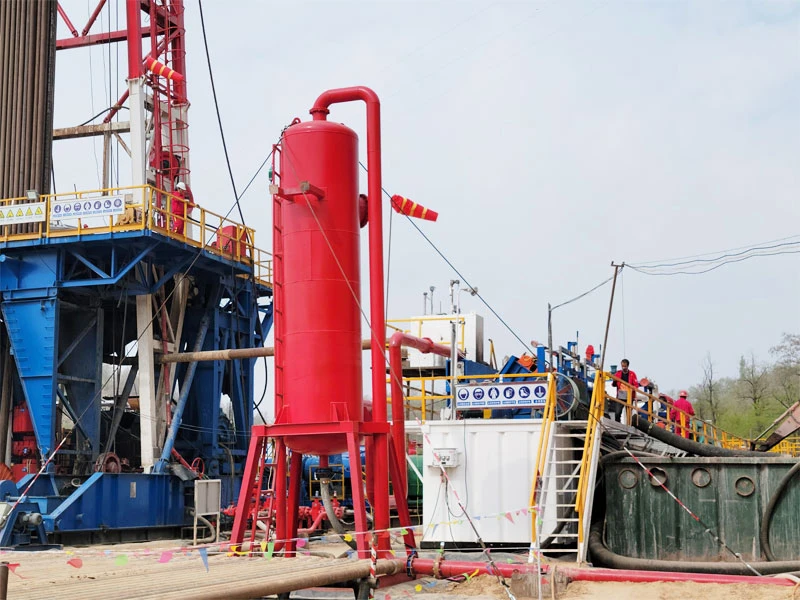

Key Solids Control Equipment

A typical solids control system includes multiple stages for progressive removal of solids by size:

-

- Shale Shakers: The first line of defense, using vibration and screens to separate larger cuttings (>75 μm) from the mud.

-

- Mud Cleaners: Combine desanders, desilters, and underflow shakers for removing finer particles (15-75 μm).

- Decanter Centrifuges: High-speed units for separating ultra-fine solids (2-7 μm) and recovering barite.

Additional equipment like vacuum degassers, mud agitators, and centrifugal pumps supports the system.

HL Petroleum offers a comprehensive range of solids control equipment, including shale shakers, mud cleaners, decanter centrifuges, desanders, desilters, and complete systems tailored to your rig requirements.

Drilling Waste Management Best Practices

Beyond solids control, effective waste management focuses on the “4 Rs”: Reduction, Reuse, Recycling, and Recovery.

-

- Waste Minimization: Optimize drilling parameters and use efficient equipment to generate less waste.

- Cuttings Treatment: Dryers and centrifuges reduce moisture content for easier handling.

- Recycling and Reuse: Recover and treat fluids for reinjection into the mud system.

- Compliant Disposal: Options include landfarming, thermal treatment, or injection, adhering to local regulations.

These practices not only ensure environmental responsibility but also significantly lower operational costs.

Why Choose HL Petroleum for Solids Control Solutions?

As a leading manufacturer of solids control equipment, HL Petroleum provides reliable, high-performance solutions for oilfield drilling, HDD, and waste treatment projects. Our products, including advanced shale shakers, centrifuges, and integrated systems, are engineered for durability, efficiency, and easy maintenance.

We offer customized designs, OEM services, and full technical support to help you achieve optimal solids control and waste management.

Contact HL Petroleum today to learn how our equipment can enhance your drilling operations while promoting sustainability and compliance.