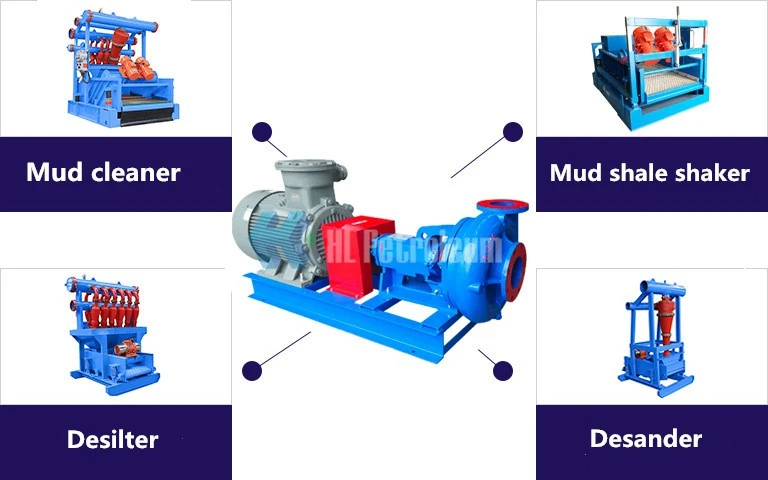

In the demanding environment of oilfield drilling, centrifugal pumps play a crucial role in maintaining efficient operations. The SB series centrifugal sand pumps, designed specifically for supporting circulating solids control systems in oilfield drilling rigs, ensure the delivery of drilling fluid with optimal displacement and pressure to equipment like desanders, desilters, and mixers. These pumps are engineered to handle the rigors of high-viscosity and high-specific-gravity drilling fluids, making them indispensable for various drilling setups.

Overview of SB Series Centrifugal Sand Pumps

The SB series offers versatile models tailored to different drilling requirements:

SB10x8x14: Ideal for drilling rigs over 3000m, especially with high-viscosity and heavy mucus fluids.

SB8x6x14: Suitable for rigs above 3000m; also serves as a feeding pump for supplying slurry to triplex mud pumps.

SB6x5x11 and SB5x4x14: Commonly used in truck-mounted or smaller drilling rigs for compact operations.

SB4x3x13: Paired with metering tanks, functioning as metering or supply pumps.

SB3x2x13: Typically employed as a clean water pump for general utility.

While these pumps are reliable, operators may occasionally encounter excessive noise during operation, which can indicate underlying issues affecting performance and safety. Understanding the causes of high noise in centrifugal pumps and implementing effective solutions is essential for minimizing downtime and ensuring smooth drilling processes.

Common Causes of High Noise in Centrifugal Sand Pumps

Excessive noise in oilfield centrifugal pumps often stems from operational inefficiencies or mechanical faults. Based on field experience, the primary reasons include:

1. Insufficient Pump Head Leading to Cavitation

If the centrifugal pump’s head (the energy imparted to the fluid) is inadequate, it may fail to draw in the drilling fluid or water from the well effectively. This results in cavitation—where vapor bubbles form and collapse within the pump—producing loud, rattling noises. Cavitation not only causes noise but can also lead to accelerated wear on impellers and other components.

2. Air Ingress Due to Pipeline Leaks or Improper Connections

Air leakage or intake in the pipeline from the well water level to the pressure tank allows air to enter the system. This disrupts the fluid flow, creating turbulence and vibrations that manifest as loud operational noise. Common culprits include loose fittings, damaged seals, or faulty connections in the suction line.

These issues are particularly prevalent in high-pressure oilfield environments where pumps like the SB series are subjected to continuous heavy-duty use.

Effective Solutions for Reducing Noise in Centrifugal Pumps

Addressing high noise promptly can prevent further damage and restore optimal performance. Here are proven troubleshooting steps:

1. For Insufficient Head and Cavitation

Solution: Upgrade to a higher-power centrifugal pump model that matches the required head and flow rate for your specific drilling conditions. For instance, if using an SB8x6x14 in a deep-well setup, consider switching to the more robust SB10x8x14 for better suction capabilities. Always verify pump specifications against site requirements to avoid mismatches.

2. For Air Ingress in Pipelines

Solution: Conduct a thorough inspection of the entire pipeline from the well water level to the pressure tank. Check for cracks, loose joints, or degraded seals that could allow air entry. Reconnect or replace faulty sections, ensuring all connections are airtight. Pressure testing the line can help identify hidden leaks.

In addition to these fixes, regular maintenance practices—such as checking impeller alignment, monitoring fluid levels, and ensuring proper priming—can prevent noise issues from arising. If noise persists after these steps, consult a professional for a detailed diagnostic, as it could indicate more complex problems like bearing failure or impeller damage.

Why Choose Xi’an HL Petroleum for Your Solids Control Needs?

At Xi’an HL Petroleum, we specialize in manufacturing high-quality solids control equipment for oilfield drilling, including the reliable SB series centrifugal sand pumps. Our team can design customized solutions and equipment tailored to your unique operational challenges, ensuring efficiency, durability, and minimal downtime. Whether you’re dealing with pump noise issues or need advanced solids control systems, we’re here to help.

If you’re interested in our products or require expert advice on centrifugal pump troubleshooting, feel free to send an inquiry to [email protected]. Let us optimize your drilling operations for peak performance.