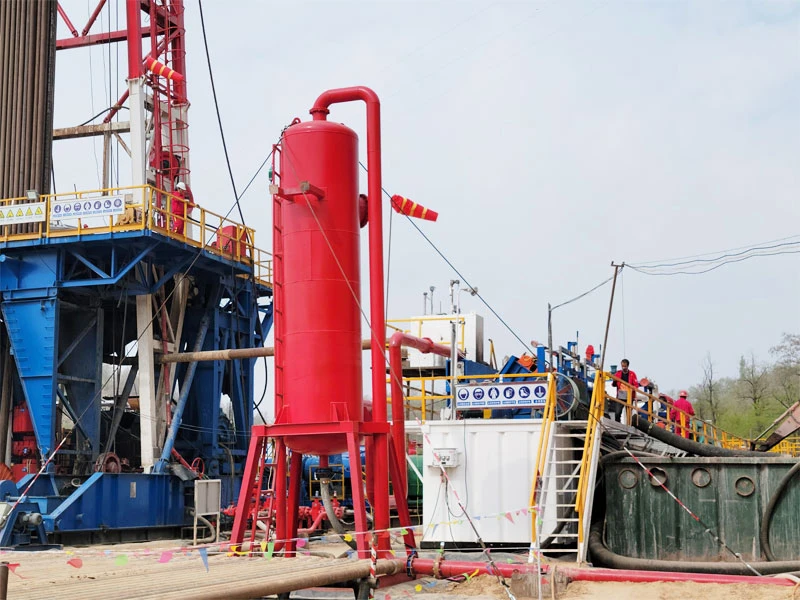

Shale shaker screens, also known as vibrating screen meshes, play a critical role in solids control systems by separating drill cuttings from drilling fluid. However, shale shaker screen service life can be significantly reduced due to several common issues. Understanding these factors helps operators minimize downtime and replacement costs in oil and gas drilling operations.

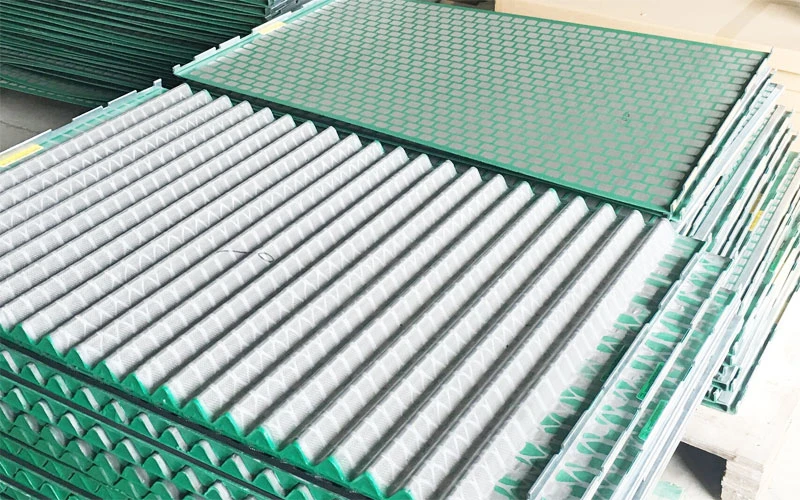

1. Poor Screen Quality

Substandard screens from unreliable manufacturers often use inferior materials or construction, leading to rapid wear, tearing, or blinding. High-quality screens with proper wire mesh and backing (e.g., stainless steel or composite frames) resist abrasion better and comply with API standards for longer durability.

2. Improper Screen Tensioning

Inadequate or uneven tension causes screen sagging, fluttering, or premature fatigue failure. Over-tensioning can also damage the mesh. Proper installation ensures the screen is flat and secure, preventing mechanical stress during vibration.

3. Damaged or Missing Protective Rubber Strips/Seals

Deck rubbers or protective strips prevent direct metal-on-metal contact and solids buildup under the screen edges. When worn, missing, or dirty, they allow cuttings to accumulate, accelerating screen damage and reducing effective screening area.

4. Incorrect Vibration Motor Rotation Direction

Especially critical for balanced elliptical motion shakers, wrong motor rotation (e.g., inward instead of outward) slows cuttings conveyance, causing prolonged residence time on the screen. This leads to excessive wear or inability to discharge solids effectively. Linear motion shakers are less sensitive, but verification is essential.

5. Material Accumulation and Excessive Flow Rate

Buildup of drill cuttings due to high viscosity, overloading, or poor flow distribution blinds the screen and increases abrasive wear. Overloading a single screen or uneven fluid distribution creates “dead zones,” reducing efficiency and shortening screen life.

Best Practices to Extend Shale Shaker Screen Service Life

Extending the lifespan of shale shaker screens not only reduces operational costs but also improves solids control efficiency and drilling fluid recovery. Follow these proven strategies for optimal performance.

1. Source High-Quality Screens from Reputable Manufacturers

Invest in screens from established suppliers with a strong reputation for quality materials (e.g., composite or polyurethane frames for abrasive conditions). Ensure compliance with API RP 13C standards for mesh sizing and conductance to guarantee durability and consistent separation.

2. Ensure Proper Installation and Tensioning

Install screens flat and evenly tensioned according to manufacturer guidelines. Avoid mechanical damage during handling. Use wedges or bolts correctly, and center panels properly. Regular checks prevent sagging, which can lead to rapid failure.

3. Maintain Protective Rubber Strips and Seals

Inspect and replace damaged or worn deck rubbers/seals promptly. Clean them regularly to prevent solids buildup. Intact protections minimize edge wear and extend overall screen usability.

4. Verify Correct Vibration Motor Direction

During setup or maintenance, confirm motor rotation per the shaker type. For balanced elliptical shakers, motors should rotate outward to promote forward conveyance. Provide operator training from the manufacturer to avoid errors based on experience with linear motion shakers.

5. Manage Material Accumulation and Flow

- Increase vibration amplitude (G-force) for sticky cuttings.

- Use spray bars (where water addition is permitted) to reduce viscosity.

- Adjust screen deck angle downward at the discharge end for gravity-assisted conveyance (monitor for mud loss).

- Optimize screen mesh size or single-screen flow rate to position the fluid “beach” near the outlet for smooth discharge.

- Ensure even distribution across multiple shakers to avoid overloading.

Additional tips include regular cleaning with low-pressure water, daily inspections for tears or blinding, and proper storage (vertical, in original packaging) to prevent damage.

By addressing these factors, operators can significantly prolong screen life, enhance drilling efficiency, and reduce waste in solids control systems. For tailored solutions in shale shakers and replacement screens, consult experienced solids control providers.