how poorboy degasser works?

Gas-invaded drilling fluid enters the degasser through the inlet, collides with the impact plate, and disperses onto a series of internal baffles. This collision and exposed surface area create turbulent flow, separating the gas from the drilling fluid. The gas outlet at the top of the tank discharges free gas. A technician determines and configures the exhaust line length on-site. The degassed drilling fluid flows through a shale shaker and into a circulation tank.

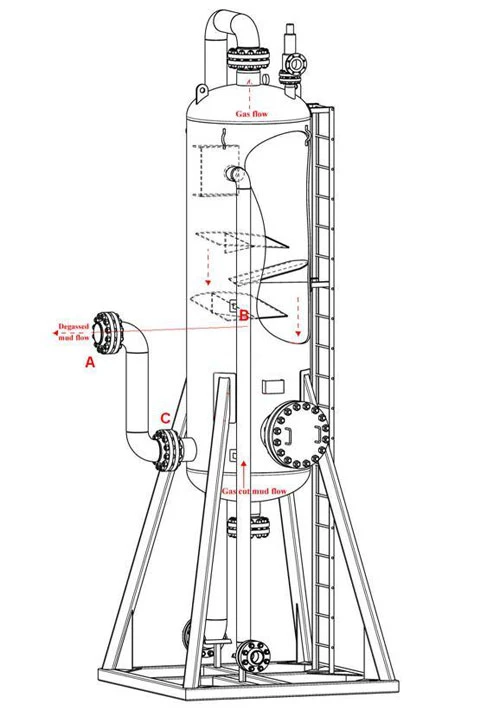

Gas-laden mud ejected from the well flows through the manifold of the choke manifold and enters the cyclone flow in the upper portion of the separator assembly. Sedimentation is the primary separation of some gas and liquid. The mud flows through the separator plates, where it is dispersed into a thin layer, exposing bubbles on their surface. This further separates the gas from the mud. The separator discharges the separated gas from its top through an exhaust pipe to a desired location. Clean mud falls to the bottom of the separator, and a drain pipe returns it to the mud tank.

The liquid level control mechanism, installed in the center of the separator, uses a mechanically controlled valve to open and close the air supply to the pneumatic butterfly valve, ensuring a constant liquid level in the separator and controlling the discharge of mud from the drain pipe while preventing aerated mud from entering the mud tank directly from the drain pipe.

The liquid level control mechanism consists of a float, a pressure regulating valve, a reversing valve, and a connecting rod piston rod. When the liquid level in the separator reaches a certain level, the float rises under buoyancy, driving the connecting rod (the piston rod) to push the reversing valve. Gas enters the pneumatic butterfly valve, opening it and discharging the liquid from the separator. When the liquid level in the separator drops to a certain level, the connecting rod (the piston rod) retracts, reversing the reversing valve and closing the pneumatic butterfly valve, stopping the discharge.

The main functions of the poorboy degassers

The main functions of the poorboy degassers are: 1. It serves as the suction port for oil and gas to enter the multi-stage centrifugal pump; 2. Before the mixed gas enters the multi-stage centrifugal pump, the separator separates free gas from the well fluid. This reduces the impact of gas on the operating characteristics of the submersible electric pump, prevents cavitation and gas lock, and ensures the normal operation of the multi-stage centrifugal pump. The gas-oil separator is a device that separates crude oil and associated natural gas produced by the oil well. Placed between the submersible centrifugal pump and the protector, the separator separates free gas from the well fluid, delivering liquid to the submersible centrifugal pump while releasing gas into the annular space between the tubing and casing.

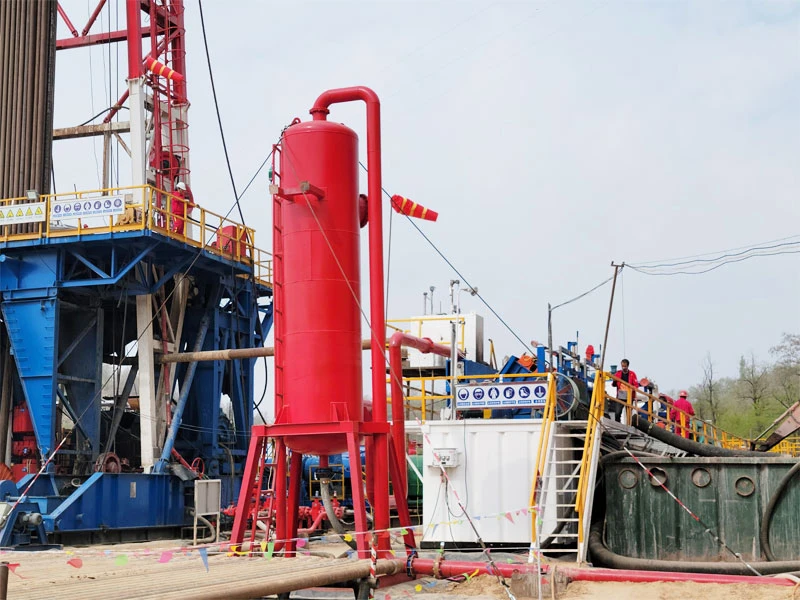

The separator is installed on the ground near the No. 1 circulating tank (near the shale shaker). Secure it to the ground with wire ropes from the four upper corners of the separator body. An ignition chamber and ignition device are installed at the exhaust line outlet.

Inspect the lower buffer plate before each use. If wear exceeds 10 mm, replace both plates before returning to service.

After each use, the drilling crew should drain the drilling fluid from the separator (especially in winter to prevent the tank from freezing and cracking) and open and clean the cleaning port or inlet.