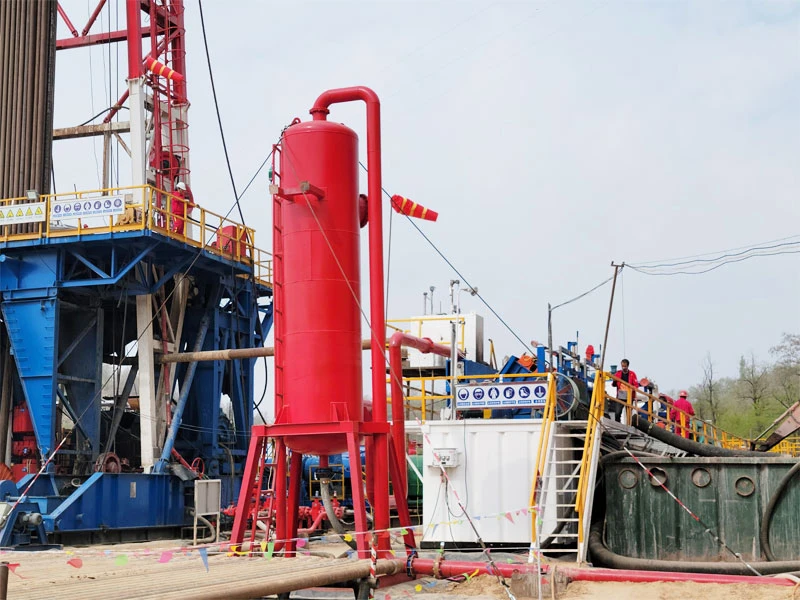

We make the atmospheric pressure, hydrogen sulfide-resistant mud gas separator for drilling fluid from high-quality materials. It effectively prevents the corrosion of harmful gases, ensuring safe production for both personnel and machinery. When drilling fluid experiences gas intrusion, its specific gravity and viscosity deviate significantly, failing to meet drilling requirements; in severe cases, if not addressed promptly, it can lead to well kicks or even blowouts. Therefore, the installation of the mud gas separator is crucial. Below, a mud gas separator manufacturer explains the installation method.

We generally install the mud gas separator on the ground next to the mud tank. The ground must be level, firm, and have pre-drilled anchor bolt pits.

During installation, use a crane to lift the main body vertically using the top lifting lugs. Slowly lower it, then use steel wire ropes to tighten it to the ground at three points (evenly distributed) on the top of the main body, ensuring its perpendicularity. Pour in the anchor bolts and tighten them.

After installation, lead the exhaust pipeline to a location 60-80m from the wellhead (the customer must supply the pipeline; if you require the manufacturer to supply it, specify this when ordering). Its inlet connects to a rotary blowout preventer or throttling manifold. Close the drain butterfly valve and open the outlet butterfly valve, then connect the pipeline to the mud tank.

During transport, remove the manifold, loosen the taut wire rope, use a crane to lift the top of the main body, loosen the anchor bolts, and place it horizontally. A ladder can be used as a transport support.

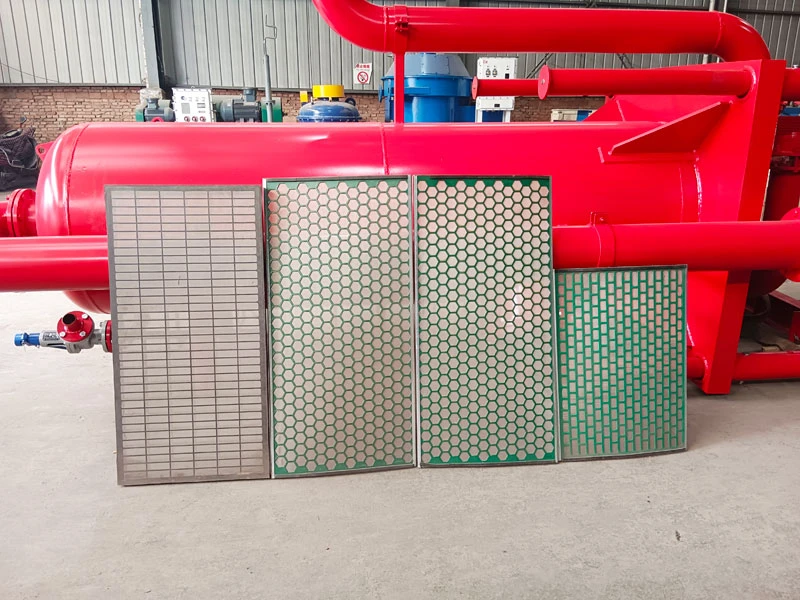

The mud gas separator is an excellent tool for separating gas from mud. Gas-leached drilling fluid enters the separator tangentially. It flows down the inner wall onto special internal baffles. Collisions with these baffles create turbulence and increase the exposed surface area. This action separates gas from the drilling fluid. Free gas discharges from the top gas outlet. Operators determine the exhaust pipe length on-site, leading it to a safe location. The degassed drilling fluid then discharges into the circulation tank.