Introduction to Oil Drilling Solids Control Systems

The solids control system uses a manifold to systematically connect four levels of separation equipment (shale shaker, degasser, desanding, desilting, and centrifuge), security equipment, and auxiliary equipment based on their separation effects.

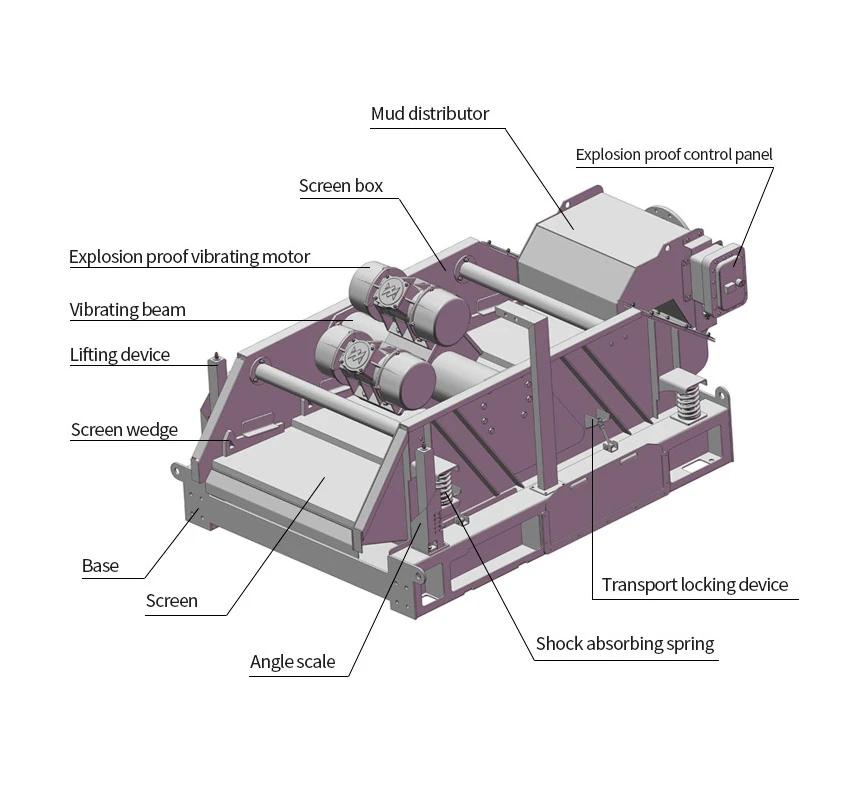

1. Primary Separation (Shale Shaker)

Drilling fluid carrying drill cuttings, held by a mud tank, first enters the vibrating screen via a diversion pipe.

-

The shale shaker separates large drill cuttings (above 74μm) from the drilling fluid.

-

The processed fluid, containing smaller particles, passes through the screen and returns to the mud tank.

2. Gas Removal (Vacuum Degasser)

If the mud contains air bubbles, a vacuum degasser‘s self-priming device draws the mud into the degasser tank for liquid-gas separation. After degassing, the mud is ready for finer solids removal.

3. Secondary Separation (Hydrocyclones)

A sand pump supplies the degassed drilling mud to the desanding and desilting cleaners. These cleaners use the principle of hydrocyclone settling and centrifugation for further solid-liquid separation.

-

The desanding cleaner separates solid particles of 45-74μm.

-

The desilting cleaner separates solid particles of 15-44μm.

The mud then enters the mud tank below the centrifuge for final separation.

4. Tertiary/Final Separation (Centrifuge)

A submersible slurry pump (screw pump) supplies the liquid to the horizontal spiral settling centrifuge.

-

Using the principle of centrifugal settling, the centrifuge can separate solid particles larger than 2μm.

Auxiliary Equipment (Mud Tanks)

Each mud tank has internal piping connections, allowing operators to extract drilling fluids with different separation effects as needed. The mud tanks also include jet mixing devices for blending the mud.

Drilling Fluid Purification System

The solids control system, also known as the drilling fluid purification system, is mainly used for solid phase control and solid-liquid separation of drilling fluid. It enables the repeated recycling of drilling mud while ensuring the stability of the drilling fluid. Solids control systems typically consist of 3-7 composite tanks, equipped with 4-stage solids control purification, chemical dosing, and weighting equipment, suitable for oil drilling projects at depths of 2000-9000 meters. This system innovatively uses composite tanks with conical bases, and a mud agitator sits on the top of the tank to prevent solids precipitation in the drilling fluid. The operators can separate or combine the mud tanks’ compartments according to the drilling process needs. A piping network interconnects each mud tank, with valves for flexible control and excellent sealing. During transportation, operators can disassemble some equipment for transport, depending on land and sea transport requirements.

Oil Drilling Solids Control System Features

1. Compact design, occupying significantly less space than traditionally installed solids control systems, allowing for flexible installation.

2. The mud tanks can hold solids control equipment and drilling fluid, effectively reducing waste in the drilling fluid and maximizing recycling.

3. All mud tanks use embedded manifolds with valves for transporting drilling fluids containing various solid phases. They are also equipped with high-quality waste discharge pipes and clean water flow pipes. 4. Includes a jet mixing device for mixing mud of different specific gravities.

5. All equipment features corrosion-resistant and wear-resistant design for a long service life.

6. The guardrails and walkways are foldable for easy disassembly and transportation.

7. Capable of withstanding harsh drilling conditions, it is cold-resistant, heat-resistant, explosion-proof, leak-proof, corrosion-resistant, and rainproof.

8. Easy to install and disassemble, and readily relocate with the drilling team.